Customized Extruded PVC Transparent Profiles: Precision, Clarity, and Performance

Our custom PVC profiles are engineered for industries requiring high optical clarity, dimensional accuracy, and chemical resistance. Designed using rigid polyvinyl chloride (PVC) and unplasticized polyvinyl chloride (UPVC), these transparent extruded profiles deliver exceptional performance in demanding environments. Ideal for applications where visibility, durability, and structural integrity are critical, these profiles are fully customizable to meet exact specifications—ensuring seamless integration into architectural, industrial, and consumer product systems.

Key Features

- High Optical Clarity: Achieves >90% light transmission with low haze, ideal for visual inspection and display applications.

- Chemical and UV Resistance: Resistant to acids, alkalis, and environmental degradation; UV-stabilized grades available for outdoor use.

- Excellent Dimensional Stability: Low moisture absorption and minimal thermal expansion ensure tight tolerances (±0.1 mm/m).

- Customizable Cross-Sections: Complex geometries, co-extrusions (e.g., PVC/ABS), and dual-color profiles supported.

- Impact and Scratch Resistance: Optional surface coatings or blended modifiers (e.g., acrylic impact modifiers) enhance durability.

- Compliance with Industry Standards: Manufactured in accordance with ISO 9001, RoHS, REACH, and UL94 V-0 flame ratings (where applicable).

Technical Specifications

Material Options

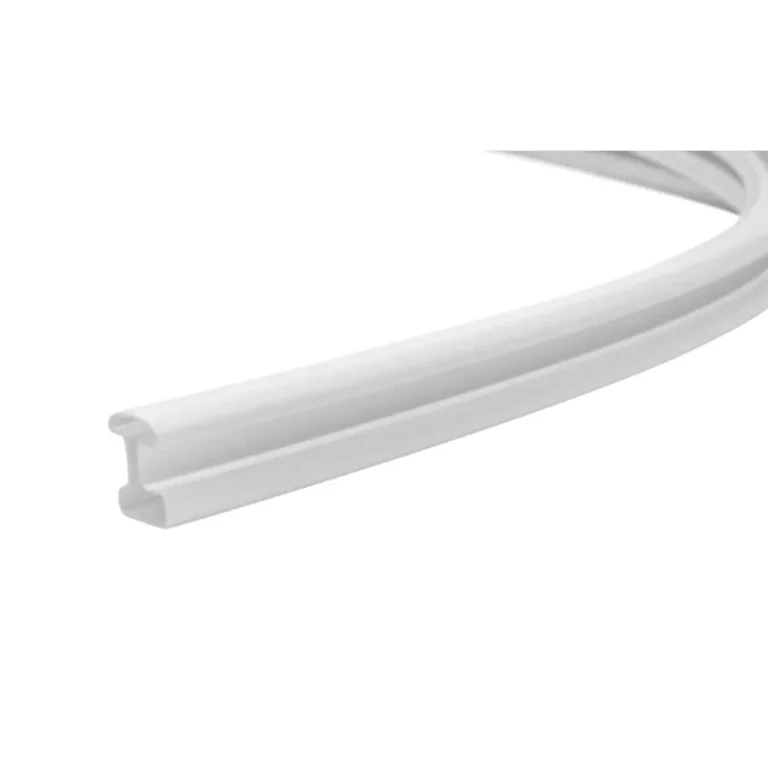

Rigid PVC/UPVC: Standard choice for high rigidity, weatherability, and flame resistance (density: 1.38–1.45 g/cm³, tensile strength: 50–80 MPa). ABS blends available for enhanced impact resistance. Polyethylene (PE) co-extrusion options for flexible edge seals.

Dimensions & Tolerances

- Cross-sectional width: 3 mm to 300 mm

- Wall thickness: 0.5 mm to 10 mm

- Length: Up to 6 meters (standard), custom lengths available

- Tolerances: ±0.05 mm (critical dimensions), ±0.2 mm (non-critical)

Applications

Widely deployed in:

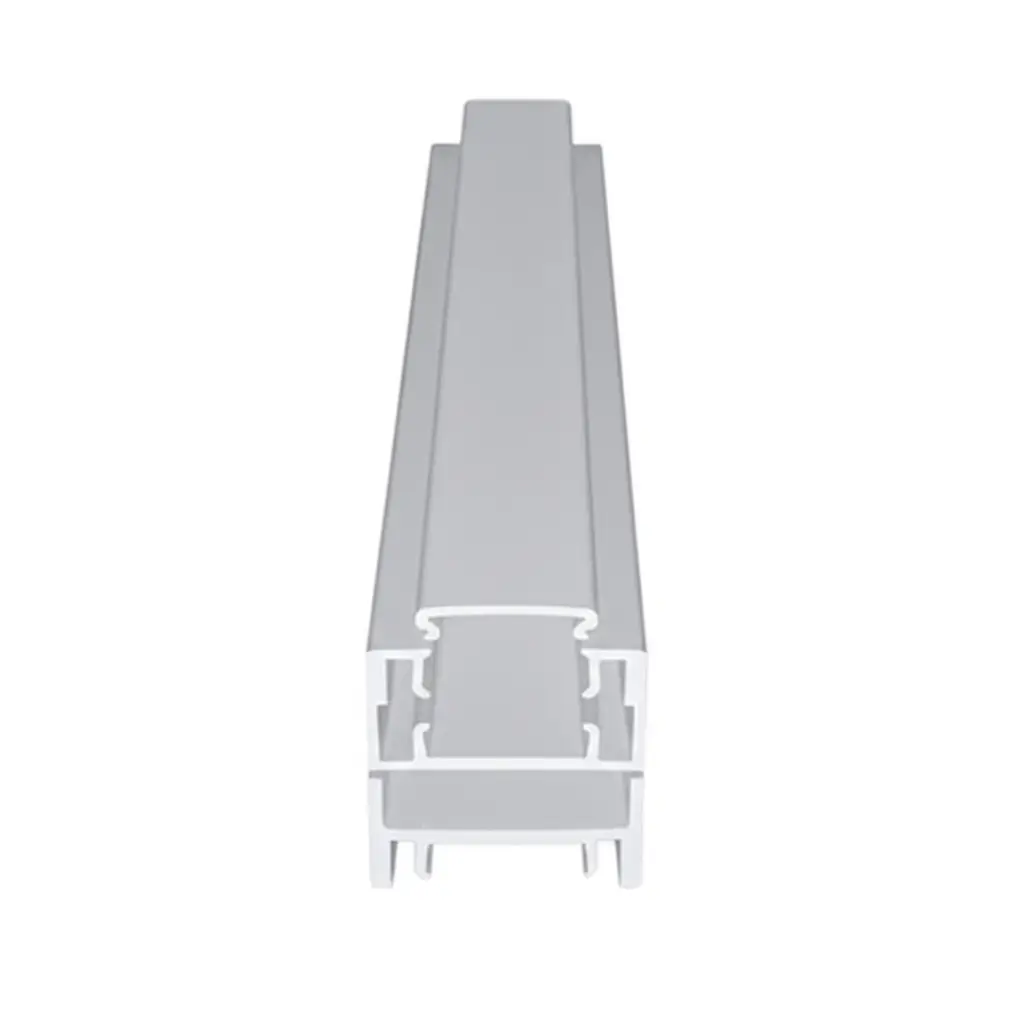

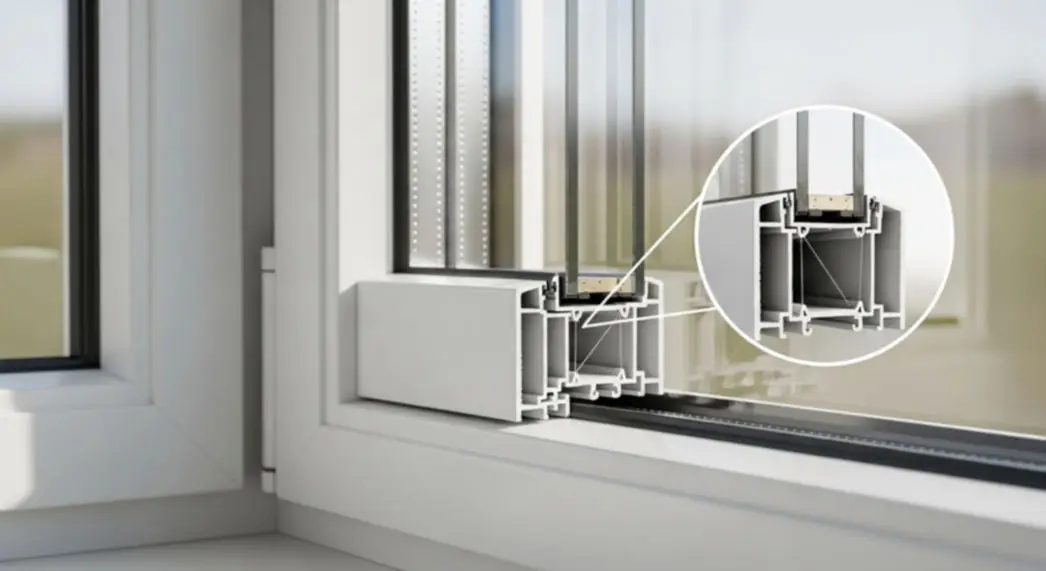

- Architectural glazing: Transparent window gaskets, door seals, and skylight profiles

- Industrial enclosures: Protective covers, machine guards, and sight windows

- Refrigeration systems: Door gaskets, transparent shelves, and display case liners

- Medical devices: Fluid flow indicators and inspection ports

- Consumer products: Display stands, signage, and protective barriers

Why Choose This Product

Our extrusion process leverages advanced tooling and in-line quality control (laser measurement, vision systems) to ensure consistent wall thickness, surface finish (Ra < 0.4 μm), and geometric precision. With our plastic extrusion solutions, clients benefit from rapid prototyping, low MOQs, and end-to-end engineering support—from design validation to mass production. Whether requiring co-extruded dual-durometer seals or multi-cavity profiles, we deliver solutions that reduce assembly costs and improve product performance.

Contact our engineering team today to discuss your project requirements and discover how our custom profiles can enhance your next application. Dalang specializes in custom extrusion services for PVC, UPVC, ABS, PE, and other plastic materials, widely used in windows, doors, refrigerators, and various applications requiring precision plastic components.