Custom UPVC & Plastic Extrusion Profiles — Engineered for Precision, Built for Performance

Bring your vision to life with precision-crafted UPVC and thermoplastic extrusion profiles — customized down to the millimeter. Whether you hand us a rough sketch, a physical sample, or a detailed CAD file, we turn your concept into a high-performance, production-ready solution. Trusted across construction, furniture, automotive, electronics, and specialty industries — we don’t just make profiles. We build the backbone of your product.

—

✅ Why Choose Us?

🎨 Total Customization — No Limits

- Color Matching: Exact Pantone or RAL color reproduction — no compromise on aesthetics.

- Shape & Size: Any cross-section. Any dimension. Send us a drawing or sample — we’ll make it happen.

- Material Flexibility: Beyond UPVC, we extrude PP, PE, PC, PA, ABS — matching material properties to your application’s demands.

⚙️ Advanced Engineering & Seamless Integration

- Drawing Compatibility: Accepts all 2D/3D formats. For best results, send STEP (.stp) or IGES (.igs) files.

- Design Software Expertise: Our engineers work fluently in UG, PRO/E, SOLIDWORKS, and AutoCAD — ready to optimize your design for manufacturability.

- Surface Finishes: Choose from high-gloss polish, matte, beveled edges — or request a custom finish.

🔩 Built to Last — Mold Life Up to 1 Million Meters

We use premium mold steel and precision CNC machining to ensure extreme durability — ideal for long-term, high-volume production. Lower cost per meter. Fewer mold replacements. Better ROI.

—

🏗️ Applications Across Industries

Our profiles are trusted worldwide in:

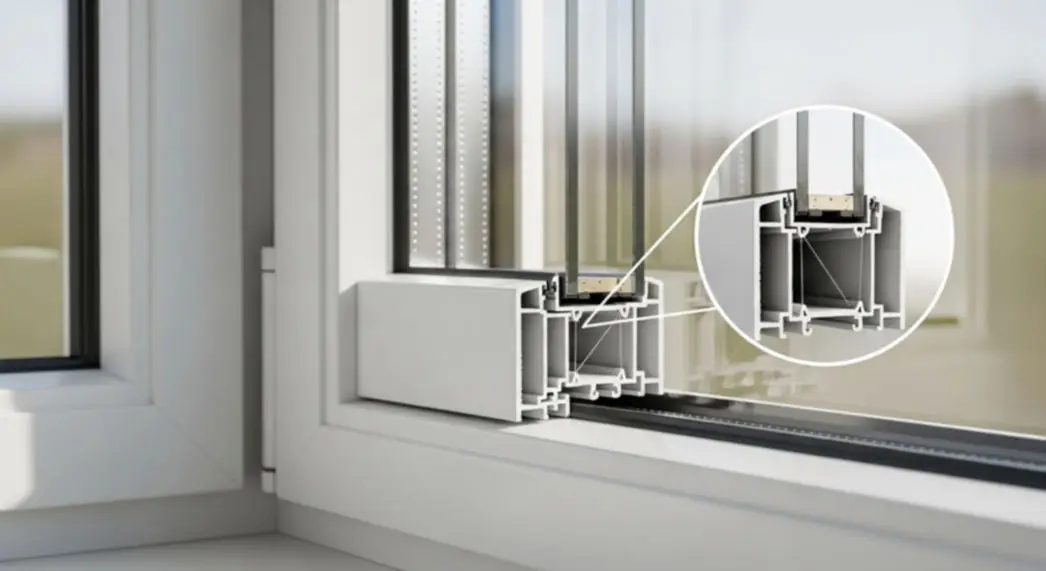

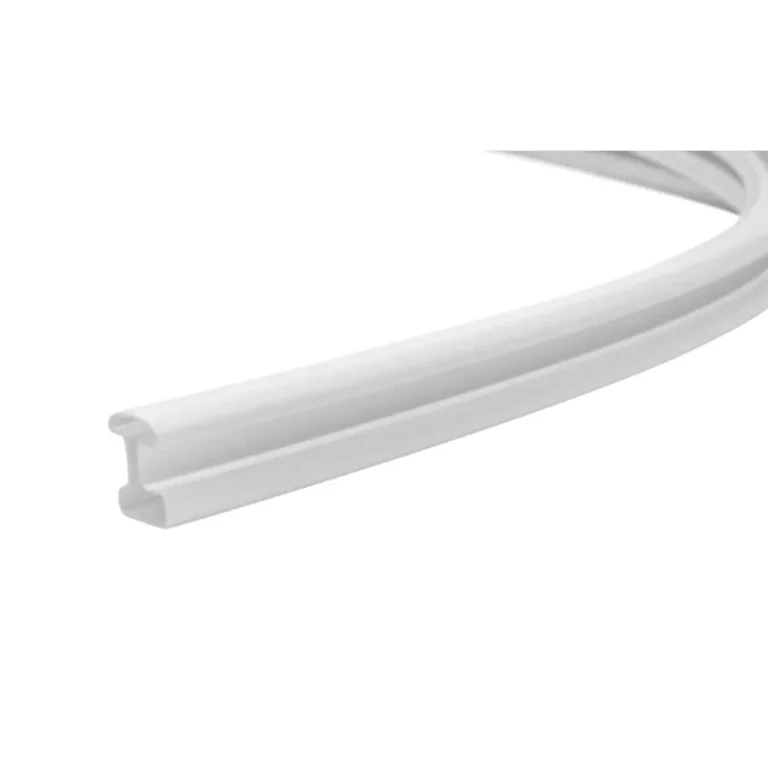

- Construction & Home: Window/door frames, refrigerator seals, cabinet edging, trim, photo frames, interior décor.

- Lighting & Display: LED diffusers, light housing, decorative lighting channels.

- Industrial & Electronics: Automotive parts, cable management, equipment frames, electronic enclosures.

- Retail & DIY: Shelf label holders, model kits, display stands, and custom fixtures.

—

🔄 Simple, Transparent Process

1. Consultation & Quote

Send us your drawing, sample, or concept. We’ll respond with a detailed quote within 24–48 hours.

2. Design Confirmation

We collaborate with you to finalize dimensions, tolerances, materials, and finishes.

3. Mold Development

- 50% deposit via T/T to begin mold production.

- Lead time: 20–25 days.

- Samples shipped for your approval.

- Remaining 50% due upon sample sign-off.

4. Mass Production

- 30% deposit via T/T to start production.

- Balance paid against copy of Bill of Lading (B/L).

- Delivery: Standard export cartons — or custom packaging on request.

📦 Flexible MOQ

From prototype runs to full-scale production — we scale with you. MOQ is negotiable. No project too small.

—

🤝 Let’s Build Together

We welcome OEM and ODM partnerships worldwide. Whether you need one custom profile or a full product line — we’re here to engineer, produce, and deliver with precision.

📩 Contact us today — and let’s turn your idea into a product that performs.