Key Features

- Automotive-Grade Material: Manufactured from high-density polyethylene (PE), this cushion strip delivers excellent impact resistance, low-temperature flexibility, and superior durability. PE offers a balance of toughness, chemical resistance, and cost-effectiveness, making it ideal for demanding automotive environments.

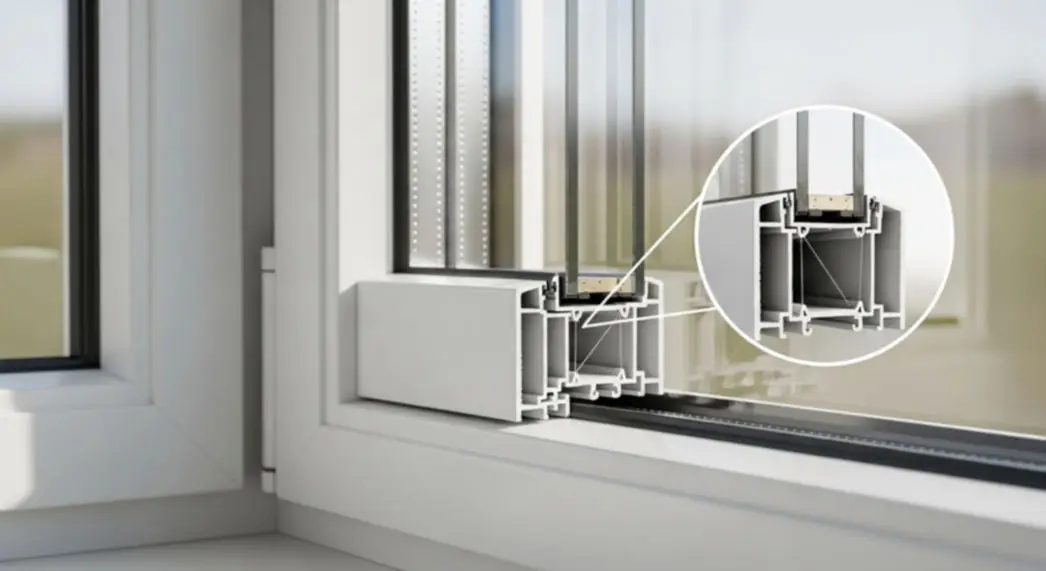

- Custom Extrusion Capability: Tailored to meet exact dimensional, profile, and performance requirements. From simple U-channels to complex multi-void geometries, we offer precision extrusion with tight tolerances (±0.15 mm typical).

- Weather & UV Resistance: Formulated with UV stabilizers and antioxidants, the PE compound ensures long-term performance in outdoor and under-hood applications, resisting degradation from sunlight, ozone, and temperature extremes (-40°C to +80°C continuous).

- Low Compression Set: Maintains sealing and cushioning properties over prolonged compression, minimizing deformation in door seals, trim, and gasketing applications.

- Noise & Vibration Damping: Engineered to absorb mechanical vibrations and reduce operational noise, enhancing cabin comfort and component longevity.

- Compliance & Quality: Meets or exceeds industry standards for automotive interior and exterior components, including ISO 9001:2015 quality management and RoHS compliance.

Technical Specifications

Material Properties

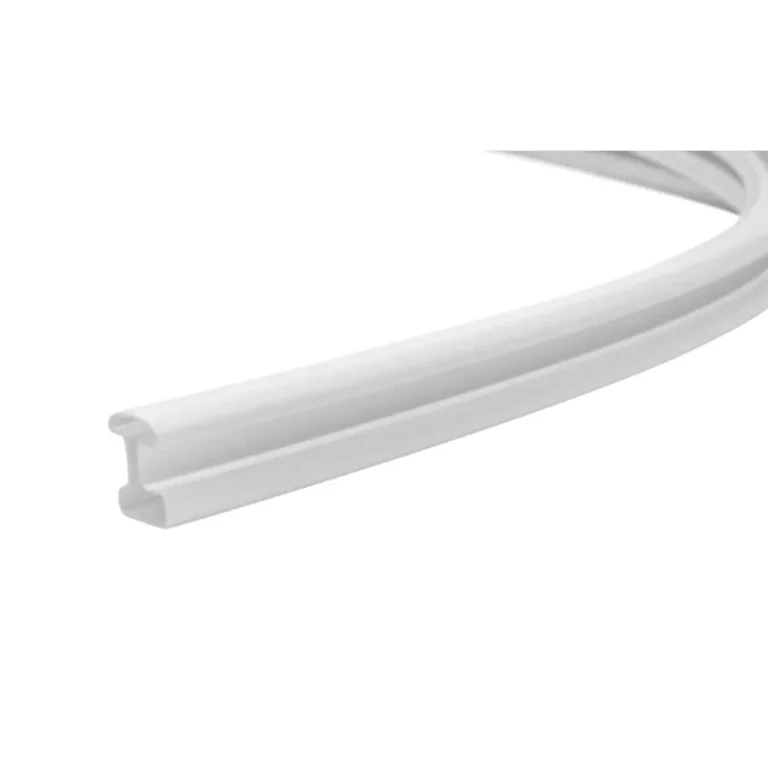

Base resin: High-density polyethylene (HDPE) or linear low-density polyethylene (LLDPE) depending on flexibility and load requirements. Density: 0.94–0.96 g/cm³. Tensile strength: 20–30 MPa. Elongation at break: 400–600%. Shore hardness: 40D–65D (customizable).

Dimensions

Cross-sectional profiles from 3 mm to 150 mm in width; wall thickness from 0.5 mm to 5 mm. Lengths up to 50 meters in continuous coils or cut-to-size segments. Co-extrusion options available for dual-durometer or color-contrasted designs.

Surface & Finish

Smooth, matte, or textured surfaces; color-matched to RAL, Pantone, or customer samples. Optional anti-static or conductive grades available.

Applications

This custom extruded PE cushion strip is engineered for critical automotive systems, including:

- Door, trunk, and hood perimeter sealing

- Interior trim and dashboard edge protection

- Headlight and taillight gasketing

- Battery pack and EV component cushioning

- Underbody and wheel well impact protection

- HVAC duct sealing and vibration isolation

Why Choose This Product

Unlike generic rubber or PVC-based alternatives, this automotive-grade PE cushion strip combines the mechanical resilience of PE with advanced extrusion precision. PE outperforms PVC in low-temperature flexibility and environmental stress cracking resistance, while offering better abrasion resistance than ABS. For specialized needs such as flame retardancy or enhanced rigidity, explore our plastic extrusion solutions, including custom PVC profiles, UPVC seals, and multi-material co-extrusions.

Dalang specializes in custom extrusion services for PVC, UPVC, ABS, PE, and other plastic materials, widely used in windows, doors, refrigerators, and various applications requiring precision plastic components.