“`html

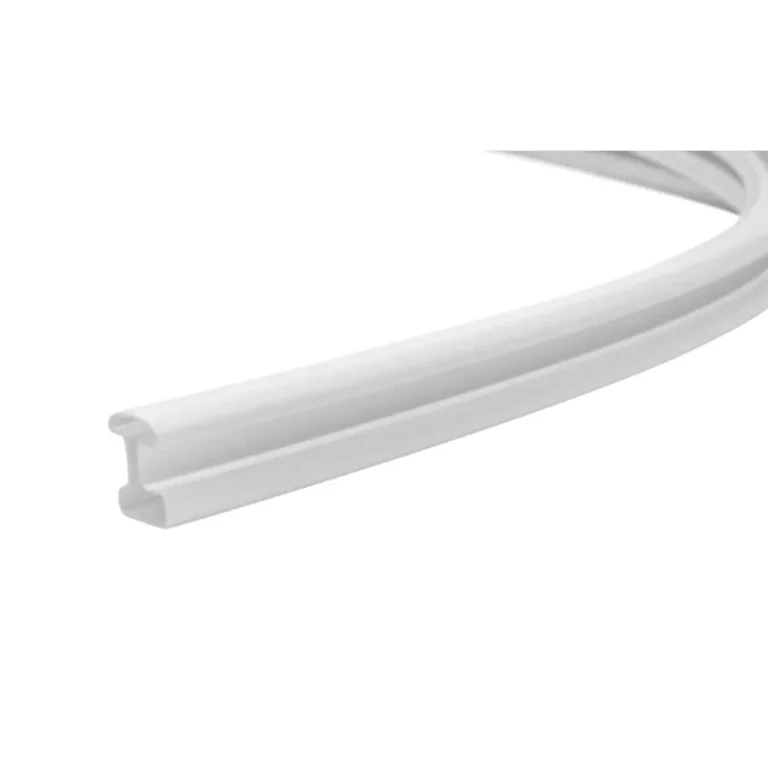

Custom Extruded Flexible PE Plastic Tubes are engineered for high-performance fluid and material transfer in demanding industrial environments. Made from premium-grade polyethylene (PE), these tubes offer exceptional flexibility, chemical resistance, and durability. Ideal for applications ranging from chemical delivery systems to medical devices and agricultural irrigation, these custom extrusions provide reliable, long-term performance under variable pressure and temperature conditions. With advanced extrusion capabilities, we deliver tubes in precise dimensions, colors, and material formulations tailored to your specifications—ensuring seamless integration into your manufacturing or operational workflow.

Key Features

- High Flexibility: Low-modulus PE formulation enables tight bending radii without kinking, ideal for dynamic installations and confined spaces.

- Chemical Resistance: Resistant to acids, alkalis, solvents, and aqueous solutions—superior to PVC and ABS in corrosive environments.

- Low-Temperature Performance: Maintains flexibility down to -50°C, outperforming rigid UPVC and ABS in sub-zero applications.

- Custom Diameters & Wall Thicknesses: Available in inner diameters from 3mm to 100mm with precise wall thickness control (0.5mm–10mm).

- Multi-Layer & Co-Extrusion Options: Reinforced layers (e.g., nylon or EVOH barriers) for enhanced pressure resistance or chemical inertness.

- Color & Marking Customization: Full-color extrusion with laser-printed text or stripes for identification and compliance.

- Smooth Inner Bore: Minimizes flow resistance and reduces particulate buildup in fluid transfer applications.

Technical Specifications

Material Properties

- Base Resin: HDPE (High-Density PE) or LDPE (Low-Density PE), with optional UV stabilizers and anti-static additives.

- Density: 0.91–0.97 g/cm³ (LDPE to HDPE range)

- Working Temperature: -50°C to +80°C (continuous), up to 100°C intermittent

- Tensile Strength: 15–30 MPa (depending on grade)

- Elongation at Break: >300%

- Compliance: RoHS, REACH, FDA-compliant grades available for food and medical use

Applications

These flexible PE tubes are widely used in:

- Chemical transfer systems in manufacturing and processing plants

- Agricultural drip irrigation and pesticide delivery

- Medical and laboratory fluid handling (non-sterile)

- Automotive fuel lines and coolant systems (with barrier layers)

- HVAC condensate drainage and pneumatic control lines

- Custom cable conduits and protective sleeving

Why Choose This Product

Our extrusion process ensures dimensional accuracy, consistent wall thickness, and surface finish across long production runs. With in-house tooling design and rapid prototyping, we support low-to-high volume production with tight tolerances (±0.1mm on diameter). All products undergo rigorous QA testing, including pressure burst tests, vacuum collapse resistance, and dimensional verification. For complex requirements, explore our plastic extrusion solutions for co-extruded, multi-lumen, or reinforced tube designs.

Contact our engineering team today to discuss your custom specifications, material selection, and volume requirements. Achieve optimal performance, cost efficiency, and supply chain reliability with precision-engineered flexible PE tubes.

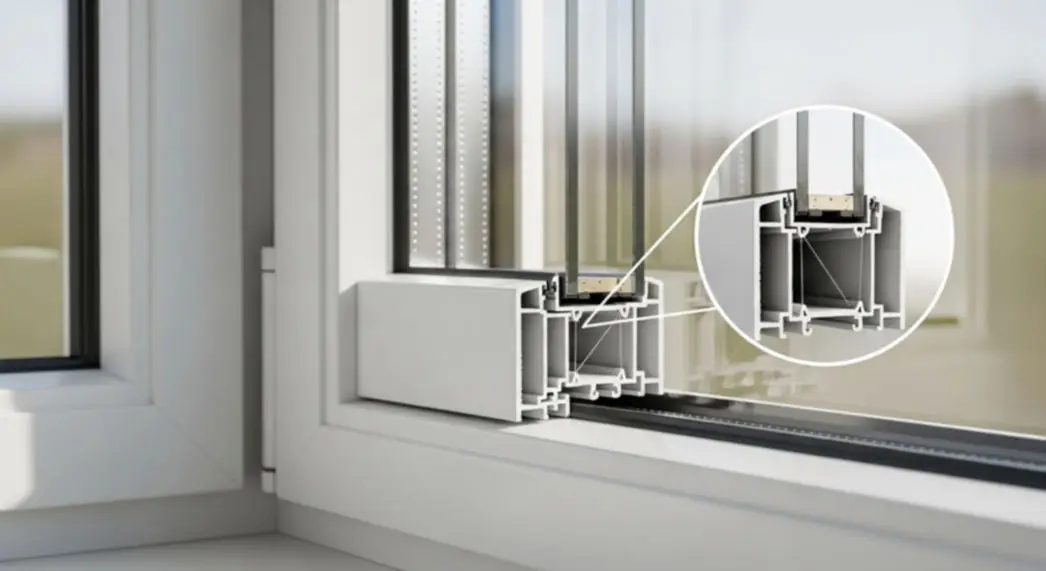

Dalang specializes in custom extrusion services for PVC, UPVC, ABS, PE, and other plastic materials, widely used in windows, doors, refrigerators, and various applications requiring precision plastic components.

“`