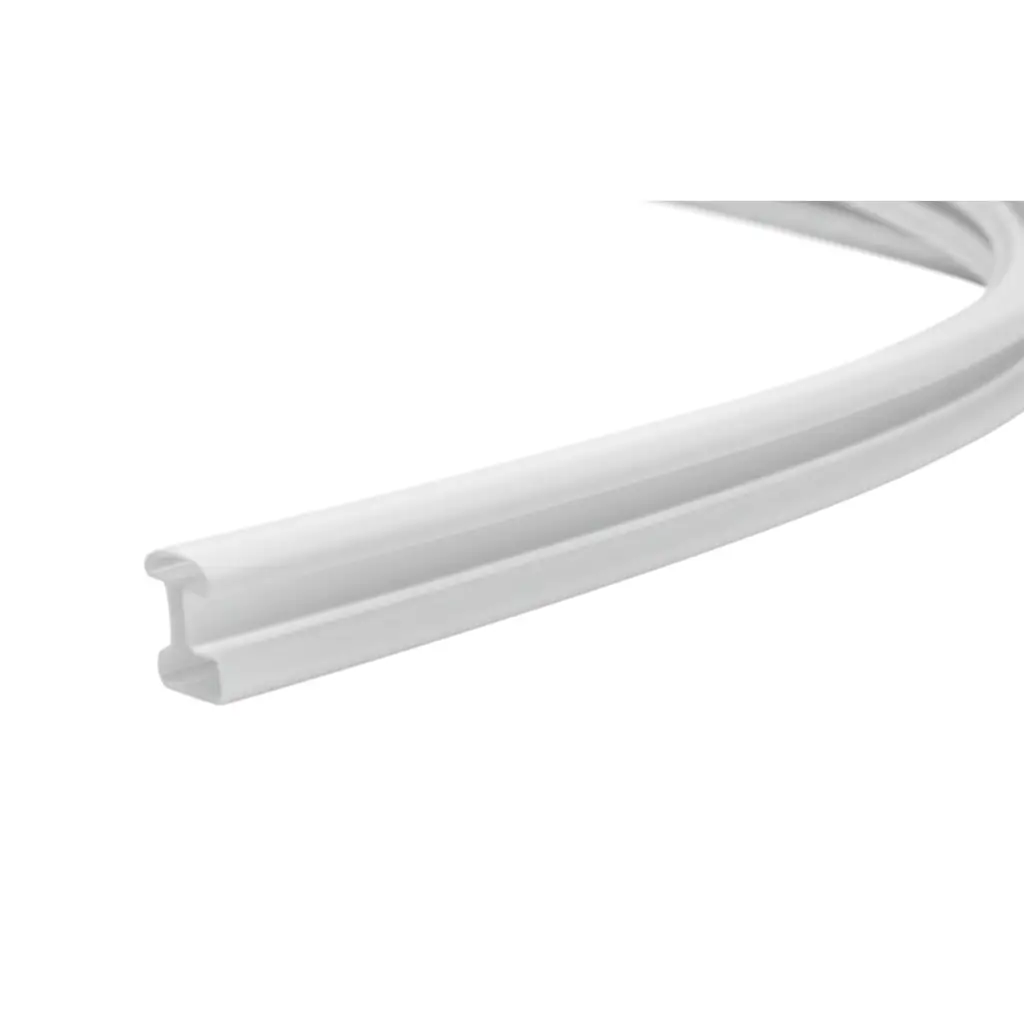

The Custom Extruded PE Plastic Furniture Decorative Edge Strip is a precision-engineered solution designed to enhance the durability, safety, and aesthetic appeal of furniture components. Fabricated from high-density polyethylene (HDPE) or low-density polyethylene (LDPE), these edge strips offer exceptional impact resistance, chemical stability, and flexibility—ideal for high-traffic environments, commercial furniture, and architectural millwork. With seamless integration capabilities, they protect vulnerable edges while adding a clean, polished finish. Fully customizable in profile geometry, color, hardness (Shore A), and surface texture, these extrusions meet exacting specifications across diverse furniture applications, from office cabinetry to retail fixtures. For advanced custom PVC profiles and multi-material extrusion capabilities, our plastic extrusion solutions deliver unmatched consistency and scalability.

Key Features

- Material Versatility: Available in HDPE and LDPE grades, offering optimal balance between rigidity (HDPE) and flexibility (LDPE) for edge protection and impact absorption.

- Custom Profile Geometry: Precision extrusion of complex cross-sections (U-channels, T-moldings, J-beads) tailored to fit edge radii from 0.5 mm to 10 mm.

- UV & Chemical Resistance: Inherently resistant to moisture, alkalis, acids, and UV degradation—ideal for both indoor and outdoor furniture applications.

- Color & Finish Options: Standard and custom color matching (RAL, Pantone), with options for glossy, matte, embossed, or textured surfaces.

- Flame Retardancy: Optional UL94 V-2 or V-0 rated formulations available for commercial and institutional furniture compliance.

- Recyclability: 100% recyclable PE material supports sustainable manufacturing and LEED compliance initiatives.

Technical Specifications

Material Properties

Base material: Polyethylene (PE) – HDPE (density: 0.941–0.965 g/cm³) or LDPE (density: 0.910–0.940 g/cm³). Tensile strength: 18–30 MPa. Elongation at break: 300–600%. Operating temperature range: -50°C to +80°C. Hardness: 45–95 Shore A (customizable).

Dimensions & Tolerances

Wall thickness: 0.8–5.0 mm. Width: 10–150 mm. Length: Standard coils (100–500 m) or cut-to-length. Profile tolerances: ±0.15 mm (critical dimensions).

Applications

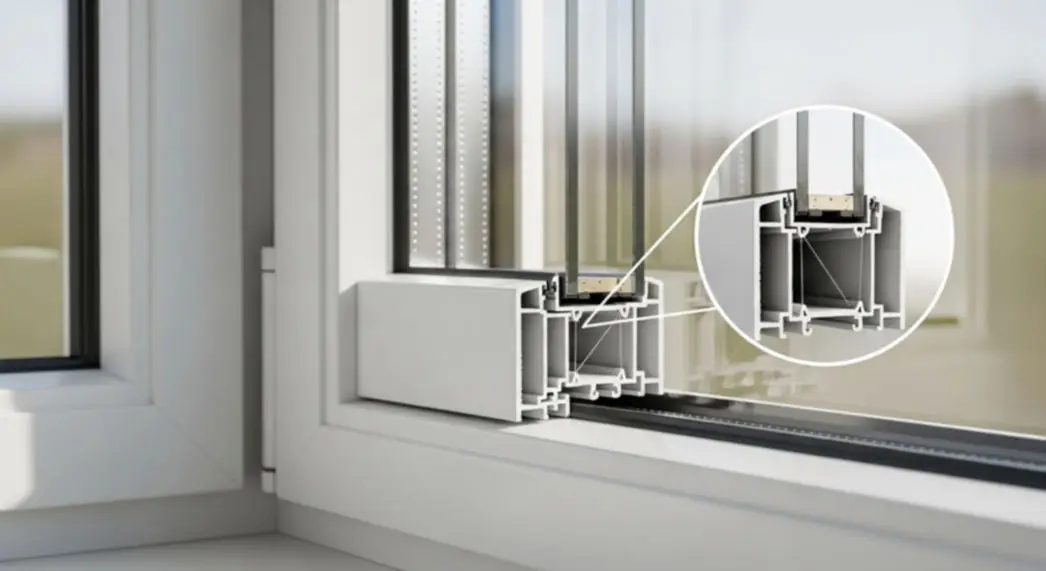

Primarily used in office desks, conference tables, cabinetry, shelving units, and retail displays. Also suitable for architectural panels, partition systems, and laboratory furniture. The edge strips protect against chipping, abrasion, and impact damage while providing a finished, decorative edge that improves user safety by eliminating sharp corners.

Why Choose This Product

This edge strip combines functional protection with design flexibility. Engineered for high-volume production, it ensures dimensional consistency across batches, reducing assembly time and rework. Our ISO 9001-certified manufacturing processes guarantee tight tolerances, uniform wall thickness, and minimal warpage. With in-house tooling design and rapid prototyping (3–5 days), we support rapid iteration and scalable production.

Explore our full range of our plastic extrusion solutions to find the ideal profile for your next project. Dalang specializes in custom extrusion services for PVC, UPVC, ABS, PE, and other plastic materials, widely used in windows, doors, refrigerators, and various applications requiring precision plastic components.