Key Features

- High-Density Polyethylene (HDPE) Construction: Engineered from premium-grade PE resin, offering exceptional chemical resistance, UV stability, and impact strength for long-term durability in harsh environments.

- Customizable Dimensions & Profiles: Precision extrusion enables tailored channel widths (10–100mm), depths (5–50mm), and lengths (up to 6m) with tight tolerances (±0.15mm) to meet specific architectural requirements.

- Integrated Grating Options: Compatible with stainless steel, aluminum, or polymer grates for load ratings up to 9000 lbs (Class D per EN 1433), ideal for pedestrian and vehicular traffic zones.

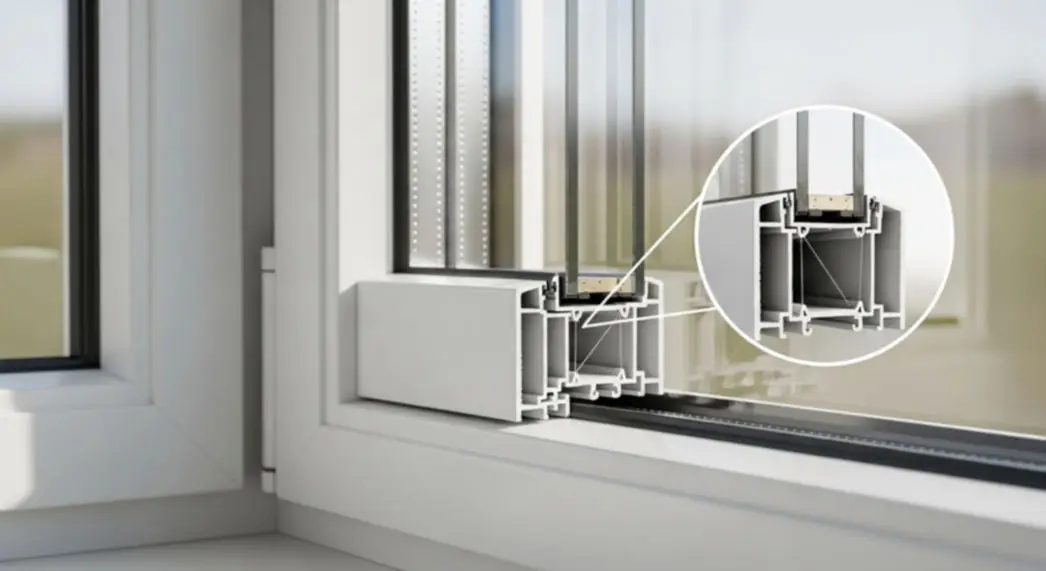

- Seamless Jointing System: Pre-engineered end connectors and gaskets ensure leak-proof installations, reducing on-site assembly time by up to 40%.

- Thermal & Acoustic Insulation: Closed-cell structure provides inherent thermal resistance (R-value: 3.2/inch) and noise reduction, critical for interior applications.

- Compliance & Certifications: Meets ASTM D3350, ISO 1183, and EN 12056 standards; available in fire-retardant (UL94 V-0) and anti-static variants.

Technical Specifications

Material Properties

Manufactured from HDPE (High-Density Polyethylene), this channel strip combines a density range of 0.941–0.965 g/cm³ with a tensile strength of 3,000–4,000 psi (20–28 MPa). The material exhibits excellent resistance to acids, alkalis, and solvents (pH 1–14), with a continuous service temperature range of -50°C to 80°C. For specialized environments, alternative materials like UPVC (rigidity, 1.3–1.45 g/cm³) or ABS (impact strength, 200–300 J/m) are available upon request.

Design & Performance

Channels feature a smooth inner wall (Ra ≤ 1.6 μm) to minimize friction (Manning’s coefficient: 0.009) and maximize flow efficiency. Wall thickness ranges from 2.5–8mm, supporting structural loads up to 500 kg/m². Customizable slope gradients (0.5%–3%) and integrated overflow ports ensure compliance with drainage regulations.

Applications

- Architectural Drainage: Roof terraces, balconies, and plaza decks with integrated water management systems.

- Commercial Infrastructure: Shopping malls, airports, and stadiums requiring high-capacity, low-maintenance drainage.

- Industrial & Municipal: Parking garages, wastewater treatment plants, and roadways with corrosive runoff.

- Green Building Projects: LEED-certified developments leveraging recyclable PE (90% post-industrial content).

Why Choose This Product

This Custom Extruded Architectural PE Drainage Channel Strip eliminates the limitations of traditional metal or concrete systems. Its lightweight design reduces structural load by 60% compared to steel, while the corrosion-resistant PE construction outperforms galvanized alternatives. With end-to-end customization—from profile geometry to color-matching (RAL/Pantone)—it seamlessly integrates into any design aesthetic. Explore our plastic extrusion solutions for tailored specifications, including co-extruded dual-material profiles or embedded RFID tags for smart infrastructure tracking.

Dalang specializes in custom extrusion services for PVC, UPVC, ABS, PE, and other plastic materials, widely used in windows, doors, refrigerators, and various applications requiring precision plastic components.