Custom Extruded PE Plastic Cable Tray Sheath: Engineered for Durability and Precision

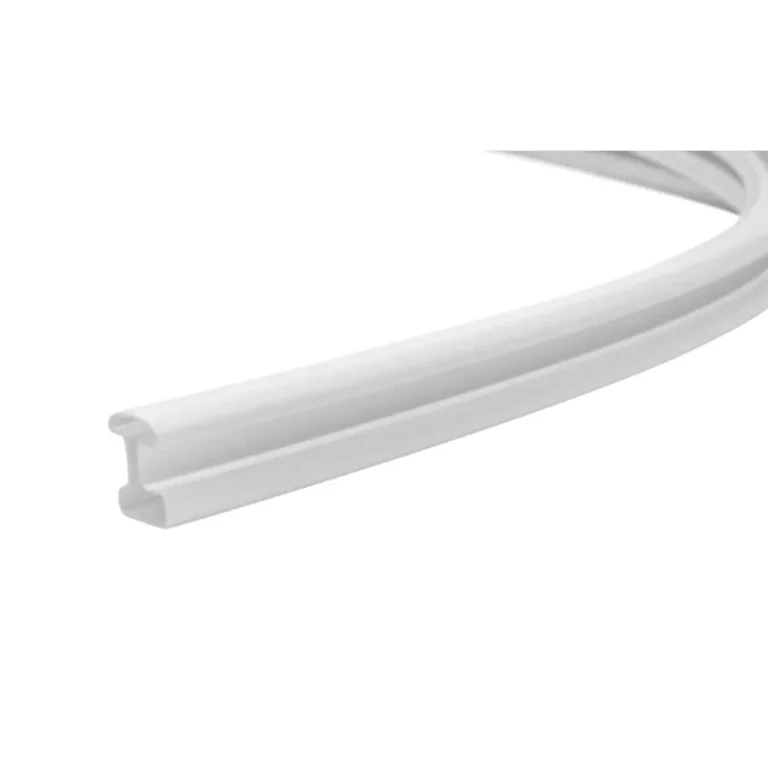

The Custom Extruded PE Plastic Cable Tray Sheath is a high-performance protective solution designed to safeguard electrical cables and wiring systems in industrial, commercial, and infrastructure applications. Manufactured from premium polyethylene (PE), this sheath offers exceptional resistance to abrasion, moisture, chemicals, and impact—making it ideal for demanding environments such as power plants, data centers, marine installations, and underground utilities. With full customization capabilities, the sheath can be tailored to fit specific cable tray geometries, ensuring seamless integration and maximum protection. Its lightweight yet robust construction simplifies installation while reducing long-term maintenance costs.

Key Features

- Material Excellence: Made from high-density polyethylene (HDPE) or low-density polyethylene (LDPE), offering superior flexibility, tensile strength, and resistance to environmental stress cracking.

- Chemical & UV Resistance: Withstands exposure to acids, alkalis, oils, and UV radiation, ensuring longevity in outdoor and harsh industrial settings.

- Flame Retardant Options: Available with V-0 flame retardant additives for compliance with fire safety standards in enclosed or high-risk areas.

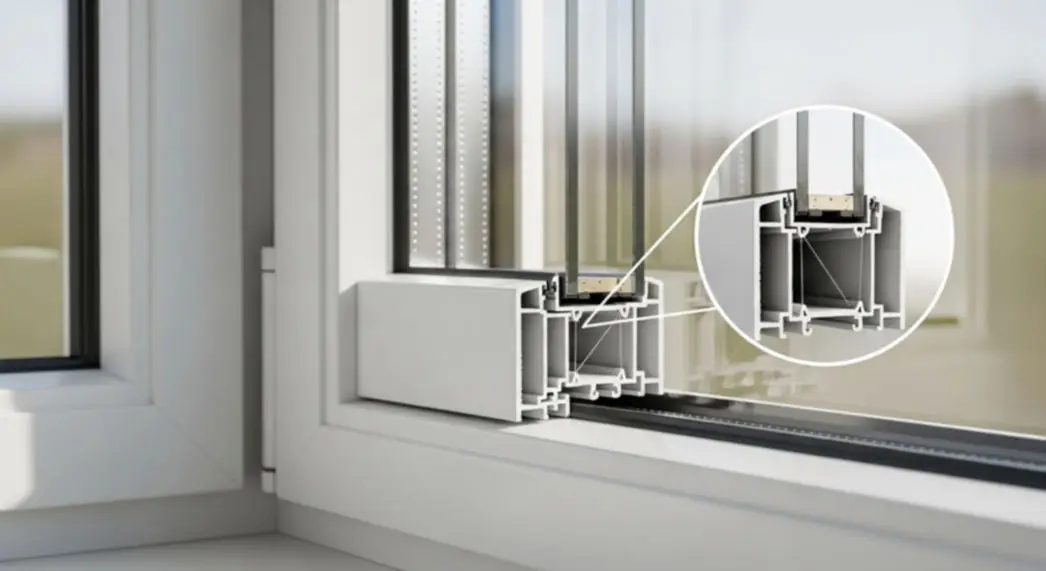

- Custom Profiles: Precision extruded to exact dimensions, including wall thickness, inner/outer diameters, and cross-sectional shapes (e.g., U-channel, C-channel, or full encapsulation).

- Smooth Interior Surface: Minimizes friction during cable insertion, reducing wear and tear on insulation.

- Color Customization: Standard colors (black, gray, white) or custom RAL/Pantone matches for identification or aesthetic alignment.

- Compliance: Manufactured to ISO 9001 quality standards and RoHS/REACH compliant materials.

Technical Specifications

Material Properties

- Density: 0.94–0.96 g/cm³ (HDPE)

- Tensile Strength: 20–30 MPa

- Elongation at Break: >400%

- Operating Temperature: -50°C to +80°C

- Water Absorption: <0.01% (24h at 23°C)

Dimensions & Tolerances

- Wall Thickness: 1.5–5.0 mm (customizable)

- Length: Up to 6 meters standard (coil options available)

- Inner Diameter: 10–200 mm (precision ±0.2 mm)

Applications

This cable tray sheath is ideal for:

- Power transmission and distribution networks

- Telecom and fiber-optic cabling in data centers

- Marine and offshore cable protection

- Underground and trench cable management

- Renewable energy installations (solar/wind farms)

Why Choose This Product

Dalang’s custom PVC profiles and extrusion solutions combine engineering precision with material science expertise. Our PE sheaths are designed for long-term reliability, reducing downtime and lifecycle costs. With in-house tooling, rapid prototyping, and batch consistency, we deliver products that meet stringent industrial requirements—from initial design to full-scale production. Explore our plastic extrusion solutions to see how we optimize performance across industries.

Contact our technical team today to discuss your cable protection needs and receive a tailored quote.

Dalang specializes in custom extrusion services for PVC, UPVC, ABS, PE, and other plastic materials, widely used in windows, doors, refrigerators, and various applications requiring precision plastic components.