Customized Extruded PVC Hollow Profiles: Precision Engineered for Diverse Industrial Applications

Customized extruded PVC hollow profiles are engineered to deliver exceptional structural integrity, dimensional accuracy, and versatility across demanding industrial environments. Constructed from rigid polyvinyl chloride (PVC), unplasticized PVC (UPVC), or specialty blends such as ABS and polyethylene (PE), these hollow profiles offer superior resistance to corrosion, moisture, UV degradation, and chemical exposure—making them ideal for applications in construction, automotive, refrigeration, and consumer goods. Designed to meet exact client specifications, these profiles provide lightweight yet robust solutions that reduce material usage, lower production costs, and enhance assembly efficiency. With advanced extrusion technology and rigorous quality control, we ensure consistent wall thickness, smooth surface finishes, and tight tolerances critical for high-performance end-use applications. Explore our plastic extrusion solutions to discover how custom PVC profiles can be tailored to your project’s unique requirements.

Key Features

- Material Flexibility: Available in standard PVC, UPVC (rigid, non-plasticized), ABS (impact-resistant), and PE (flexible, low-friction) to suit mechanical, thermal, and environmental demands.

- Hollow Cavity Design: Optimized for weight reduction, improved insulation (thermal/acoustic), and internal routing of cables, fluids, or structural elements.

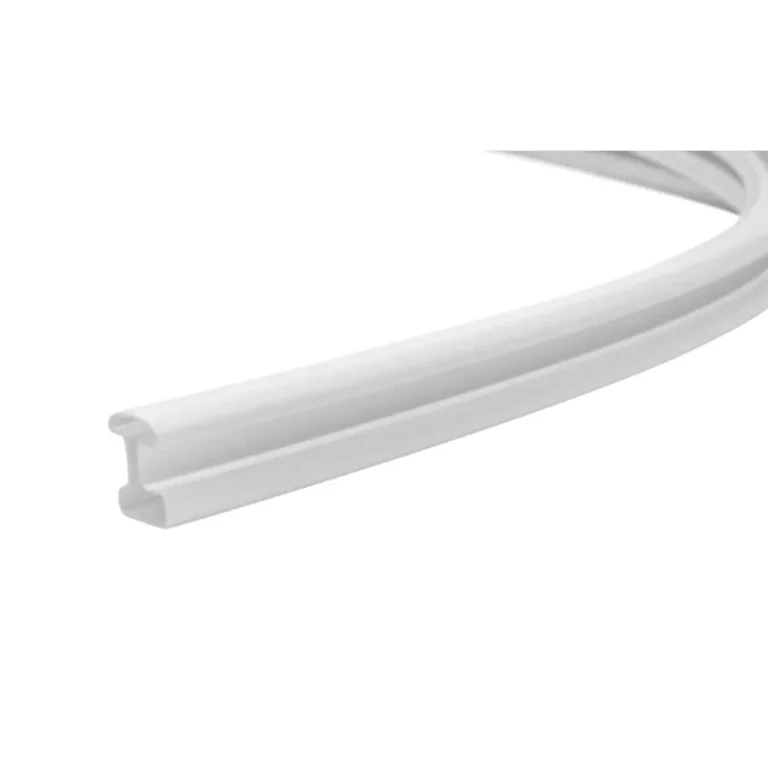

- Custom Geometry: Precision extrusion of complex cross-sections including multi-chamber, ribbed, or tapered hollow profiles with consistent wall thickness (±0.1 mm tolerance).

- Surface Finishes: Options include matte, gloss, textured, or co-extruded layers for enhanced aesthetics, grip, or wear resistance.

- UV & Weather Resistance: UPVC variants offer excellent outdoor durability with minimal expansion/contraction under thermal cycling.

- Flame Retardancy: Compliant with UL94 V-0, ASTM E84, and other international fire safety standards upon request.

- Recyclable & Eco-Friendly: PVC profiles are fully recyclable and meet RoHS, REACH, and WEEE compliance.

Technical Specifications

Profiles are manufactured using state-of-the-art twin-screw extrusion lines with real-time monitoring for dimensional stability. Standard specifications include:

- Profile Width: 5 mm to 300 mm

- Wall Thickness: 0.5 mm to 10 mm (customizable)

- Length: Continuous coils or cut-to-length (up to 6 meters standard)

- Density: 1.35–1.45 g/cm³ (PVC/UPVC)

- Tensile Strength: 45–60 MPa (PVC), 50–65 MPa (ABS)

- Thermal Deflection Temperature: 60–80°C (at 1.82 MPa load)

- Color & Additives: Custom color matching, UV stabilizers, anti-static, and antimicrobial agents available

Applications

Widely deployed in industries requiring precision-engineered hollow sections, these profiles serve as:

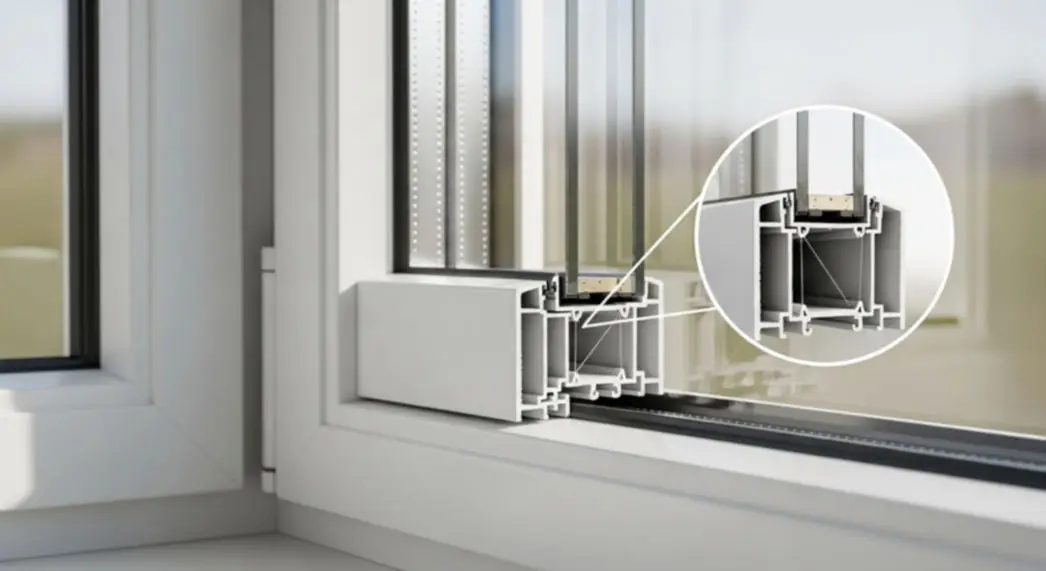

- Window and door frames (UPVC for thermal break systems)

- Refrigerator liners and insulation channels

- Conduit housings for electrical wiring

- Automotive interior trims and underbody shields

- Furniture edging, display stands, and modular shelving

- HVAC ducting and ventilation components

Why Choose This Product

Our customized extruded PVC hollow profiles combine engineering excellence with scalable production. With in-house tooling design, rapid prototyping, and ISO 9001-certified manufacturing, we ensure repeatable quality and fast turnaround. Whether you need small-batch specialty profiles or high-volume production runs, our solutions reduce lead times and optimize material efficiency.

Partner with us to leverage advanced our plastic extrusion solutions and achieve superior performance, cost savings, and design flexibility.

Dalang specializes in custom extrusion services for PVC, UPVC, ABS, PE, and other plastic materials, widely used in windows, doors, refrigerators, and various applications requiring precision plastic components.