Customized Extruded PVC Groove Cover Profile: Precision, Durability, and Versatility

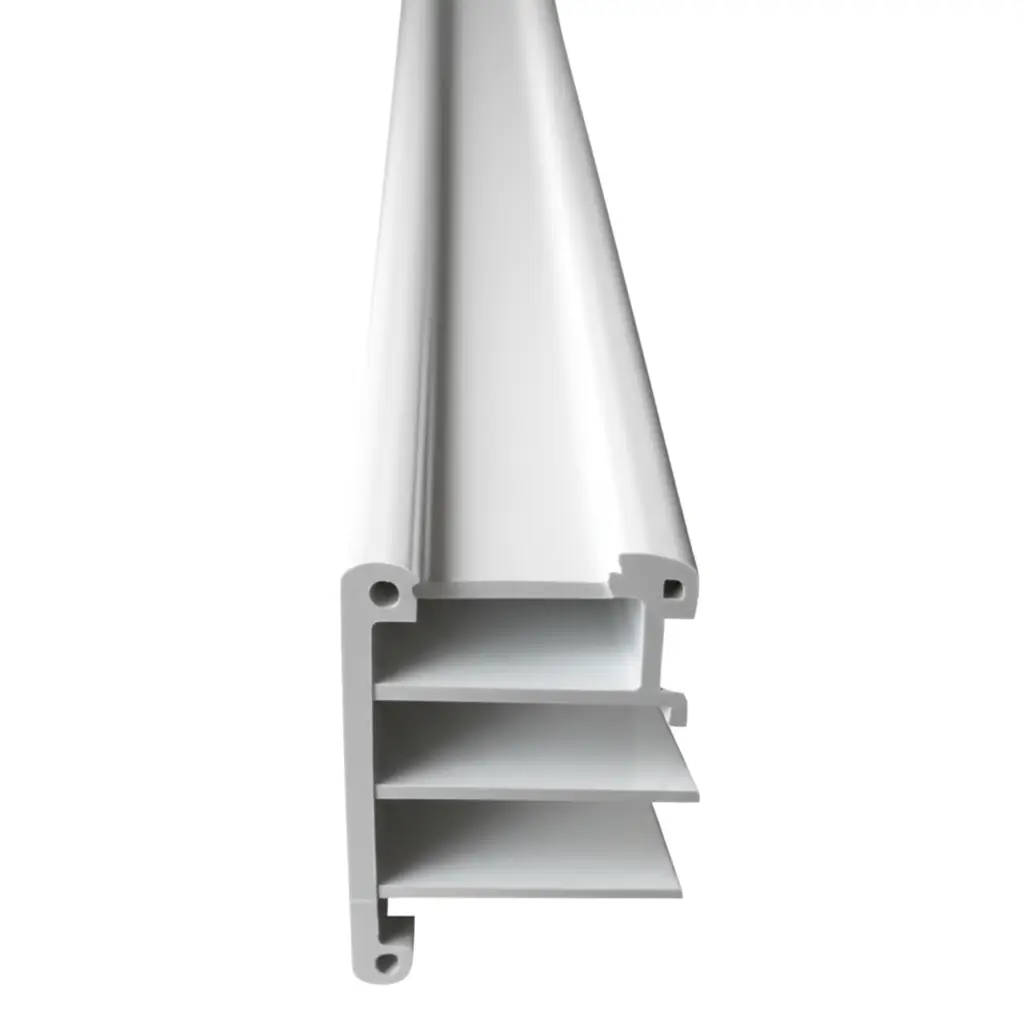

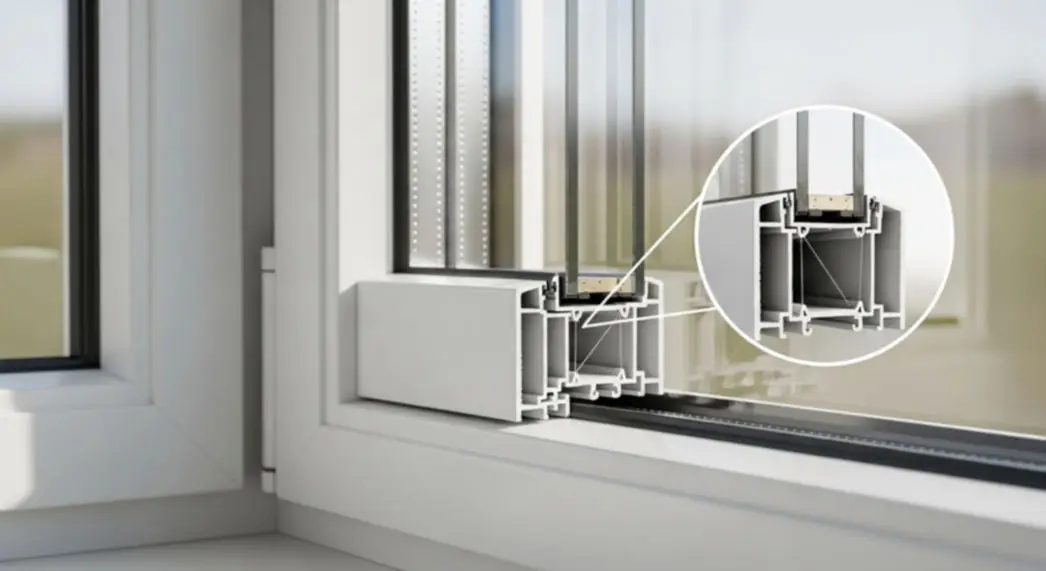

The Customized Extruded PVC Groove Cover Profile is a high-performance plastic extrusion engineered to protect, seal, and enhance the structural integrity of groove-based assemblies. Manufactured from premium-grade rigid PVC (polyvinyl chloride) or UPVC (unplasticized PVC), these profiles deliver exceptional resistance to moisture, chemicals, UV degradation, and mechanical wear. Designed for seamless integration into industrial, architectural, and manufacturing environments, they are ideal for covering grooves in metal frames, machinery housings, flooring systems, and construction components. With advanced customization capabilities, these profiles ensure precise fit, optimal performance, and long-term reliability across demanding applications.

Key Features

- Material Excellence: Available in rigid PVC and UPVC, offering high tensile strength (45–60 MPa), low water absorption (<0.1%), and excellent dimensional stability.

- Custom Geometry: Tailored cross-sectional designs (e.g., T-groove, U-channel, L-edge) to match specific groove dimensions and load requirements.

- Weather & Chemical Resistance: Resistant to acids, alkalis, salts, and UV exposure, making them suitable for both indoor and outdoor applications.

- Flame Retardancy: Complies with UL94 V-0 standards for fire safety in enclosed environments.

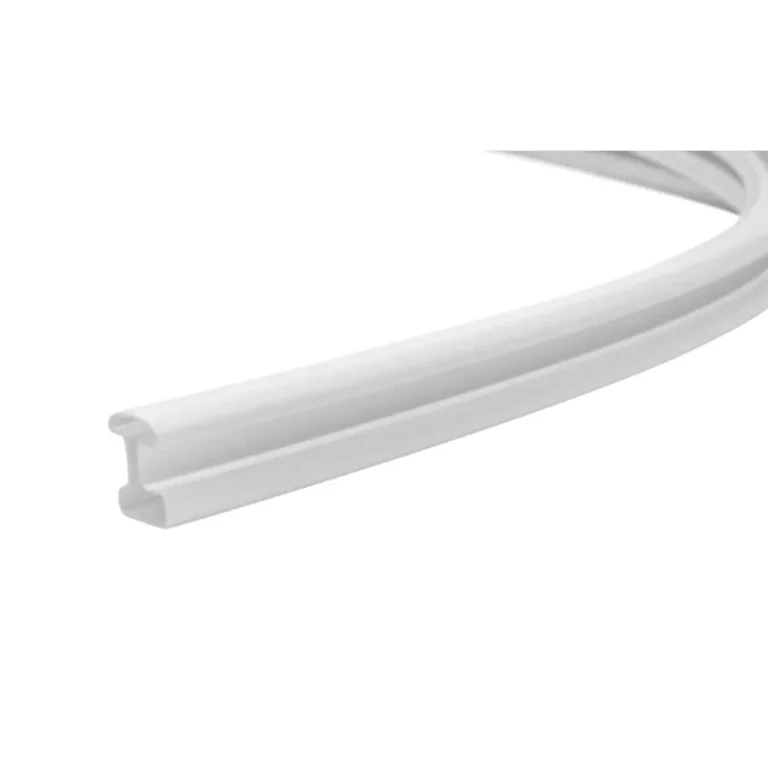

- Color & Finish Options: Standard black/white; customizable colors, surface textures (matte, gloss, embossed), and dual-extrusion with flexible PVC or TPE seals.

- Thermal Stability: Operating temperature range from -20°C to 60°C, with optional heat-resistant grades for higher thermal loads.

- Low Maintenance: Non-porous surface prevents bacterial growth and simplifies cleaning.

Technical Specifications

Material Properties

Base materials include rigid PVC (density: 1.38–1.45 g/cm³, tensile modulus: 2,500–3,500 MPa) and UPVC (enhanced rigidity and impact resistance). Alternative materials such as ABS (for higher impact strength) and HDPE (for flexibility and chemical resistance) can be specified based on application needs. Wall thickness ranges from 0.8 mm to 6 mm, with lengths customizable up to 6 meters.

Quality Standards

Manufactured under ISO 9001-certified processes, profiles undergo rigorous quality control, including dimensional accuracy checks, tensile testing, and accelerated aging tests. All materials meet RoHS and REACH compliance.

Applications

Widely used in window and door frame systems, industrial machinery enclosures, HVAC ducts, flooring transitions, elevator tracks, and electrical panel grooves. Their sealing function prevents debris ingress, dampens vibration, and improves aesthetics in modular construction and OEM assemblies.

Why Choose This Product

Unlike standard off-the-shelf solutions, our profiles are engineered to exact specifications, ensuring perfect fitment and eliminating gaps or misalignment. With in-house tooling design and rapid prototyping, we deliver custom PVC profiles with short lead times and scalable production volumes. Whether for high-volume manufacturing or specialized retrofitting, our extrusion process guarantees consistency, repeatability, and cost-efficiency.

Optimize your assembly performance with our plastic extrusion solutions—contact our engineering team today to discuss your custom requirements.

Dalang specializes in custom extrusion services for PVC, UPVC, ABS, PE, and other plastic materials, widely used in windows, doors, refrigerators, and various applications requiring precision plastic components.