The Customized Extruded PVC Assembled Profile is a precision-engineered solution designed for industries requiring durable, lightweight, and highly customizable plastic components. Fabricated from high-grade PVC (Polyvinyl Chloride), UPVC (Unplasticized PVC), and optionally blended with ABS or PE for enhanced performance, these profiles deliver exceptional dimensional stability, chemical resistance, and long-term reliability. Ideal for applications in construction, refrigeration, industrial enclosures, and consumer products, these assembled profiles combine extrusion precision with modular assembly techniques to meet complex design requirements. With full customization in geometry, color, and mechanical properties, our profiles are engineered to integrate seamlessly into existing systems while reducing assembly time and material waste.

Key Features

- Material Flexibility: Standard PVC and UPVC formulations for rigidity and UV resistance; optional ABS (Acrylonitrile Butadiene Styrene) for impact strength or PE (Polyethylene) for flexibility and low-temperature performance.

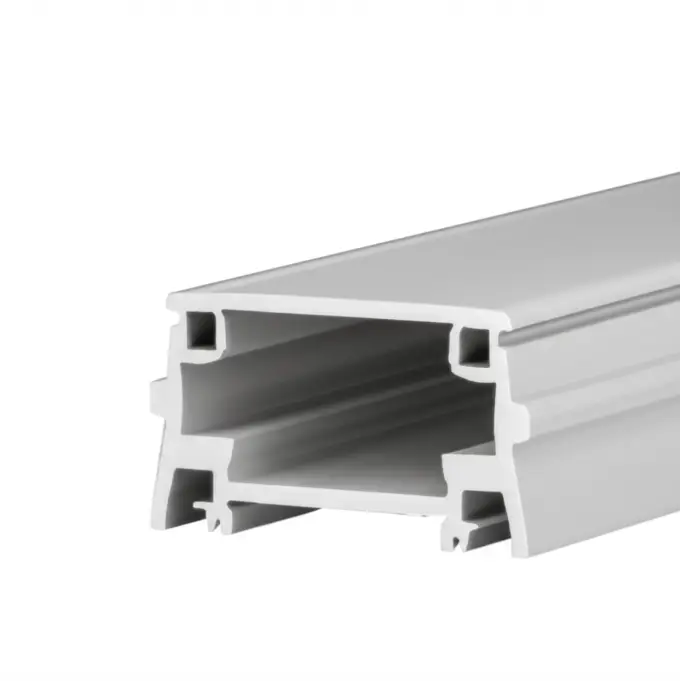

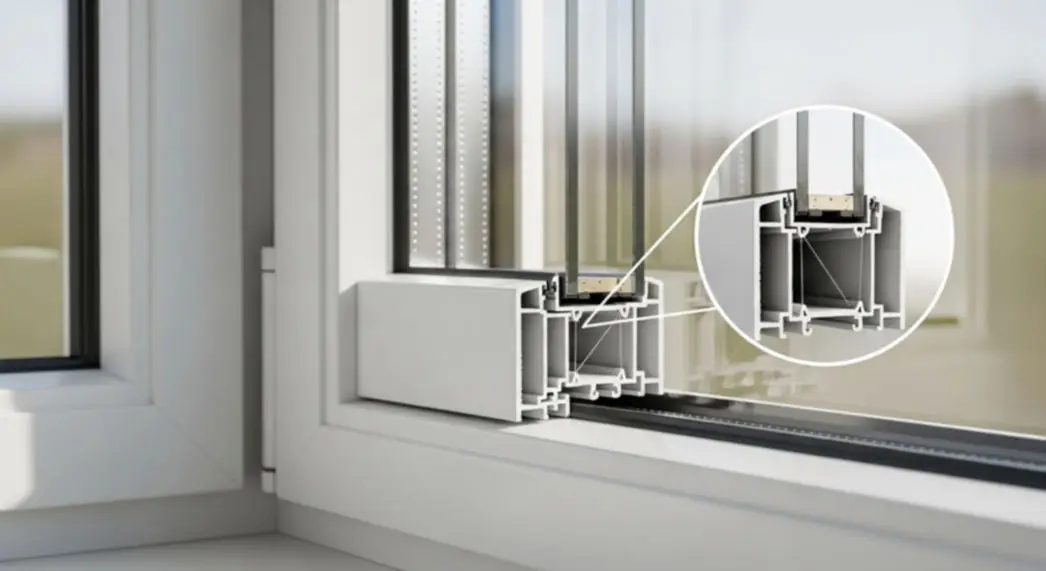

- Custom Cross-Sectional Geometry: Complex hollow, multi-cavity, and co-extruded designs achievable via CAD-driven die tooling.

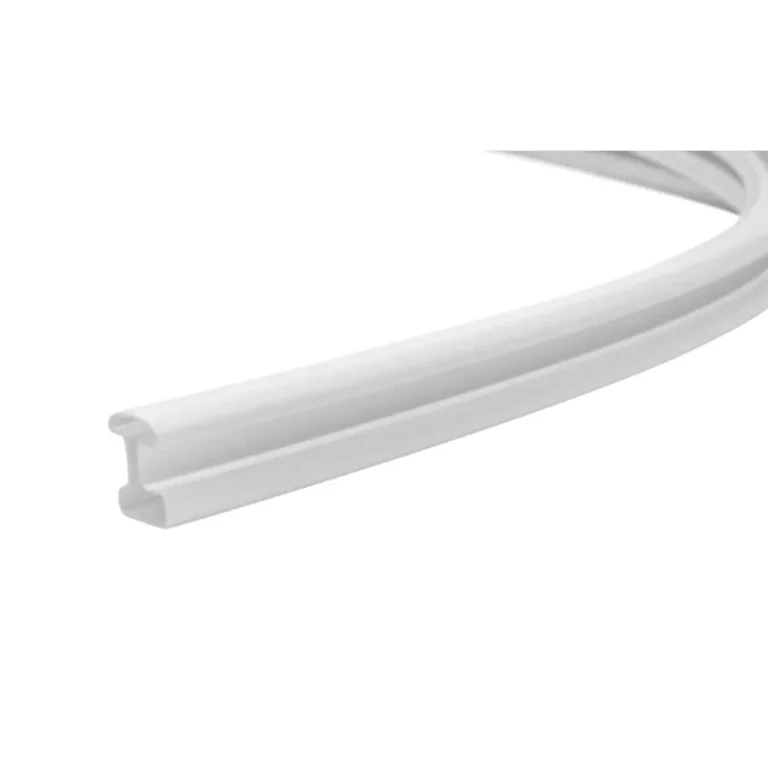

- Integrated Assembly Features: Pre-molded snap-fits, tongue-and-groove joints, and adhesive channels to enable rapid, tool-free assembly.

- Surface Finishes: Available in smooth, textured, or laminated finishes with optional color matching (RAL/Pantone) and anti-static or flame-retardant additives (UL94 V-0 rated).

- Environmental Resistance: Excellent resistance to moisture, acids, alkalis, and most solvents; UPVC variants provide superior weatherability for outdoor use.

- Compliance: Manufactured in accordance with ISO 9001:2015 standards and RoHS/REACH directives.

Technical Specifications

Material Properties

- Density: 1.38–1.45 g/cm³ (PVC/UPVC)

- Tensile Strength: 40–60 MPa (PVC), 35–55 MPa (ABS)

- Flexural Modulus: 2,800–3,200 MPa (UPVC)

- Thermal Stability: Continuous use up to 60°C (PVC), 80°C (ABS)

- Shore Hardness: 75–90D (PVC), 100–115R (ABS)

Production Capabilities

- Profile Length: 0.5m to 6m (custom lengths available)

- Tolerance: ±0.2mm (standard), ±0.05mm (high-precision)

- Wall Thickness: 0.8mm to 10mm

- Co-Extrusion: Multi-material layers (e.g., rigid core with soft sealing edge)

Applications

- Construction: Window/door frames, glazing gaskets, and cladding systems requiring weatherproofing.

- Refrigeration: Door seals, cabinet liners, and internal partitions with low outgassing properties.

- Industrial: Conveyor guides, machine guards, and electrical conduit housings.

- Consumer Products: Furniture edging, display stands, and modular shelving.

Why Choose This Product

Our custom PVC profiles leverage advanced extrusion technology to deliver turnkey solutions that reduce downstream processing. By integrating assembly features directly into the profile design, we eliminate secondary operations, lowering total cost of ownership. With in-house tooling design, rapid prototyping, and batch consistency, we ensure scalable production for high-volume OEMs and specialized low-volume applications. All profiles undergo rigorous QA, including dimensional inspection, tensile testing, and accelerated aging.

Explore how our plastic extrusion solutions can streamline your next project. Contact our engineering team to discuss your specific requirements. Dalang specializes in custom extrusion services for PVC, UPVC, ABS, PE, and other plastic materials, widely used in windows, doors, refrigerators, and various applications requiring precision plastic components.