Custom Extruded ABS Industrial Components deliver precision-engineered solutions for demanding industrial applications, combining the superior mechanical properties of Acrylonitrile Butadiene Styrene (ABS) with advanced extrusion capabilities. Designed for durability, dimensional accuracy, and customization, these components are ideal for manufacturers in the automotive, electronics, construction, and appliance industries. With excellent impact resistance, thermal stability, and chemical resistance, extruded ABS profiles offer a cost-effective alternative to metal and other thermoplastics without sacrificing performance. Whether you require complex cross-sections, tight tolerances, or integrated functional features, our custom extrusion process ensures consistent quality and rapid scalability.

Key Features

- High Impact Strength: ABS offers exceptional toughness, even at low temperatures, making it ideal for rugged industrial environments.

- Thermal Stability: With a heat deflection temperature of up to 95°C (1.82 MPa), ABS maintains structural integrity under moderate thermal loads.

- Chemical & Solvent Resistance: Resistant to many acids, alkalis, and aqueous solutions, suitable for harsh industrial settings.

- Excellent Dimensional Accuracy: Precision tooling and controlled extrusion lines ensure ±0.15 mm tolerances for critical fit applications.

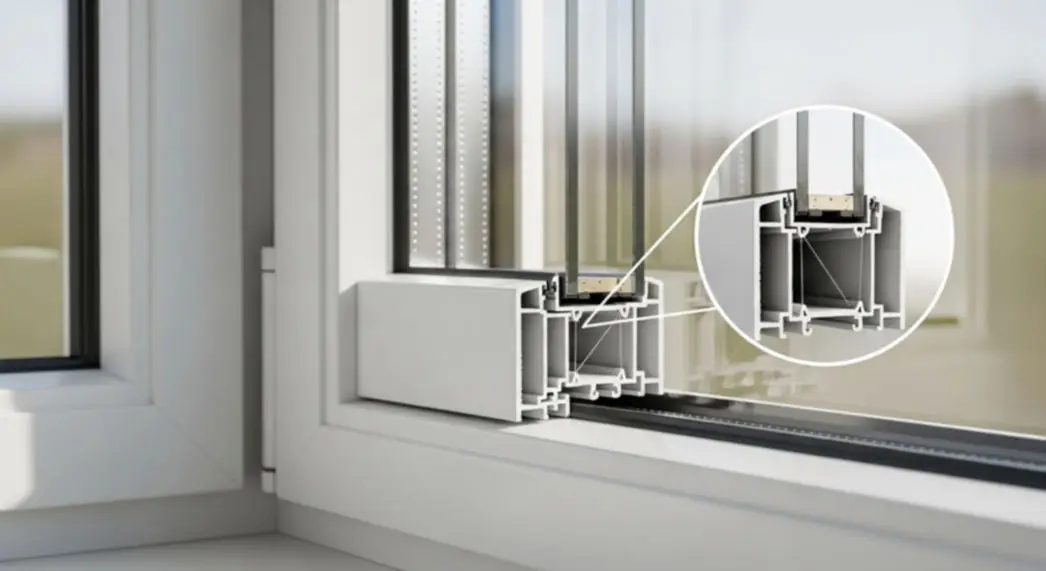

- Customizable Geometry: Complex hollows, ribs, snap-fits, and co-extruded seals can be integrated into a single profile.

- Surface Finishes: Available in smooth, textured, or embossed finishes; compatible with post-extrusion painting, printing, or plating.

- Flame Retardant Options: UL94 V-0 rated grades available for electronics and safety-critical components.

Technical Specifications

Material Properties (ABS)

- Density: 1.04–1.07 g/cm³

- Tensile Strength: 40–50 MPa

- Flexural Modulus: 2.1–2.5 GPa

- Shore Hardness: R100–115

- Vicat Softening Point: 95–105°C (50°C/h, 50N)

Extrusion Capabilities

- Profile Widths: Up to 300 mm

- Wall Thickness: 0.5 mm to 10 mm

- Lengths: Continuous coils or cut-to-length (up to 6 meters)

- Secondary Operations: Drilling, notching, punching, and assembly integration

Applications

Custom extruded ABS components are widely used in appliance housings (refrigerator liners, washing machine panels), automotive interior trim, electronics enclosures, HVAC ducting, and industrial equipment guards. Their balance of rigidity, processability, and surface quality also makes them suitable for point-of-purchase displays and medical device housings.

Why Choose This Product

Our advanced extrusion lines support tight-tolerance manufacturing with consistent material distribution and minimal warpage. We offer full design support, including CAD modeling, mold flow analysis, and rapid prototyping. All components meet ISO 9001 quality standards and can be tailored to meet industry-specific certifications. For complex multi-material assemblies, explore our plastic extrusion solutions, including co-extruded ABS/PVC or ABS/TPU profiles for enhanced sealing and flexibility.

Partner with a manufacturer that delivers precision, scalability, and engineering excellence. Request a sample or technical consultation today to optimize your next project. Dalang specializes in custom extrusion services for PVC, UPVC, ABS, PE, and other plastic materials, widely used in windows, doors, refrigerators, and various applications requiring precision plastic components.