Custom Extruded ABS Profiles: Precision, Durability, and Versatility

Our Custom Extruded ABS Profiles are engineered to meet the demanding requirements of modern industrial applications. Made from Acrylonitrile Butadiene Styrene (ABS), a high-performance thermoplastic known for its superior impact resistance, dimensional stability, and excellent processability, these profiles offer a robust solution for manufacturers seeking durable, cost-effective, and fully customizable components. Whether used in structural, decorative, or functional roles, our ABS extrusions deliver consistent performance across diverse environments, including automotive, electronics, construction, and consumer goods.

Key Features

- High Impact Strength: ABS inherently resists impact and mechanical stress, making it ideal for high-wear applications.

- Excellent Dimensional Stability: Maintains tight tolerances (±0.15 mm) even after thermal cycling and long-term use.

- Chemical & UV Resistance: Resists oils, greases, and many solvents; UV-stabilized grades available for outdoor exposure.

- Low Moisture Absorption: Minimizes warping and maintains structural integrity in humid or wet conditions.

- Customizable Surface Finishes: Options include smooth, matte, textured, and embossed finishes to match aesthetic requirements.

- Color Matching & Co-Extrusion: Available in standard and custom Pantone/RAL colors; dual-material (e.g., rigid/flexible) co-extrusion for functional integration.

- Compliance: Meets ISO 9001, RoHS, REACH, and UL94 V-0 flame retardancy standards (on request).

Technical Specifications

Material Properties (ABS)

- Density: 1.04–1.07 g/cm³

- Tensile Strength: 40–50 MPa

- Flexural Modulus: 2,000–2,400 MPa

- Heat Deflection Temperature (0.45 MPa): 95–105°C

- Shore Hardness: R105–R115

- Thermal Expansion Coefficient: 80–90 × 10⁻⁶/K

Available in cross-sections up to 300 mm wide, with wall thicknesses from 0.5 mm to 10 mm. Tight tolerance control ensures seamless integration with mating components. For projects requiring alternative materials, explore our plastic extrusion solutions, including custom PVC profiles and UPVC alternatives for enhanced weatherability or PE for flexibility.

Applications

Custom extruded ABS profiles are widely used in:

- Automotive: Interior trim, dashboard components, door panels

- Electronics: Enclosures, housings, structural supports for consumer and industrial devices

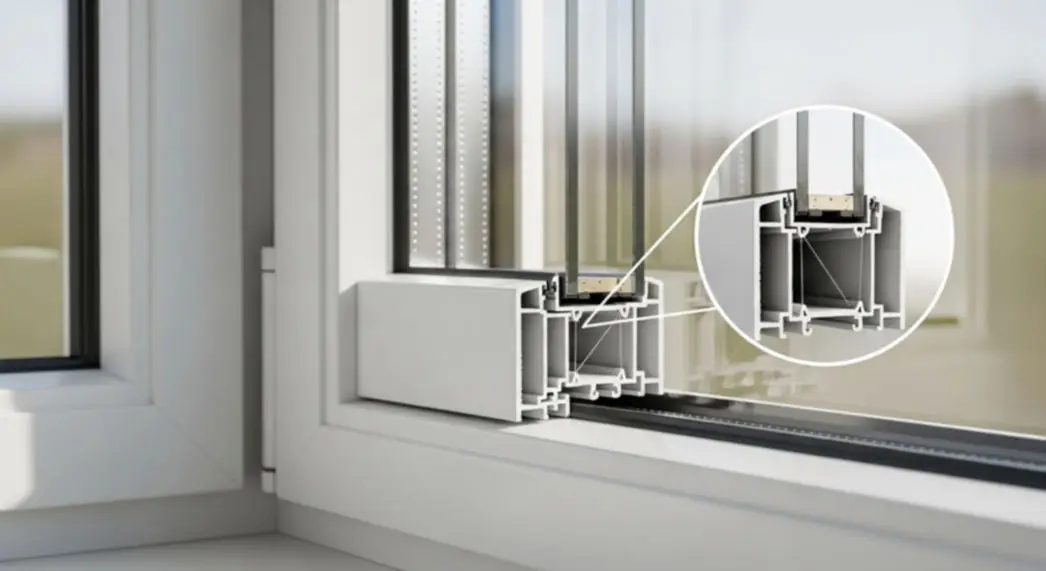

- Construction: Window/door frames, skirting, edge trims

- Appliances: Refrigerator liners, washing machine parts, vacuum cleaner components

- Furniture: Edge banding, decorative moldings, modular shelving

Why Choose This Product

Our ABS profiles combine material excellence with advanced extrusion technology. We support rapid prototyping, low-volume production, and high-volume manufacturing with full design-for-manufacturability (DFM) support. From CAD modeling and tooling to post-extrusion fabrication (cutting, drilling, printing), every step is optimized for quality and efficiency. With in-house material formulation and rigorous QC testing (including dimensional inspection, mechanical testing, and visual checks), we ensure each profile meets exacting specifications.

Ready to optimize your next project? Contact our engineering team to discuss your custom requirements and discover how our ABS extrusion capabilities can enhance your product performance and reduce total cost of ownership.

Dalang specializes in custom extrusion services for PVC, UPVC, ABS, PE, and other plastic materials, widely used in windows, doors, refrigerators, and various applications requiring precision plastic components.