Custom High Flowability & Easy-to-Process Extruded ABS Profiles

Engineered for precision and efficiency, our Custom High Flowability & Easy-to-Process Extruded ABS Profiles are designed to meet the demanding requirements of modern manufacturing. These profiles leverage acrylonitrile butadiene styrene (ABS)—a thermoplastic renowned for its balanced strength, impact resistance, and processability. By enhancing ABS with high flowability properties, these extrusions reduce cycle times, improve dimensional stability, and enable intricate designs with minimal post-processing. Ideal for industries requiring complex geometries, tight tolerances, and consistent performance, these profiles are widely adopted in automotive, electronics, construction, and consumer goods. Whether replacing metal components or optimizing existing plastic systems, our ABS extrusions deliver superior cost-efficiency and design flexibility.

Key Features

- High Flowability Formulation: Reduces melt viscosity, enabling faster filling of molds and complex cross-sections with minimal pressure, lowering energy consumption and tool wear.

- Enhanced Processability: Low warpage and shrinkage ensure high dimensional accuracy, even in thin-walled or large-format profiles.

- Excellent Impact Resistance: ABS’s inherent toughness withstands mechanical stress, making it ideal for structural or load-bearing components.

- Superior Surface Finish: Smooth, consistent surface quality reduces need for secondary finishing, saving time and labor.

- Thermal Stability: Maintains integrity in temperatures ranging from -20°C to 80°C, suitable for indoor and outdoor applications.

- Chemical & UV Resistance: Resists common solvents, greases, and UV degradation, ensuring long-term durability.

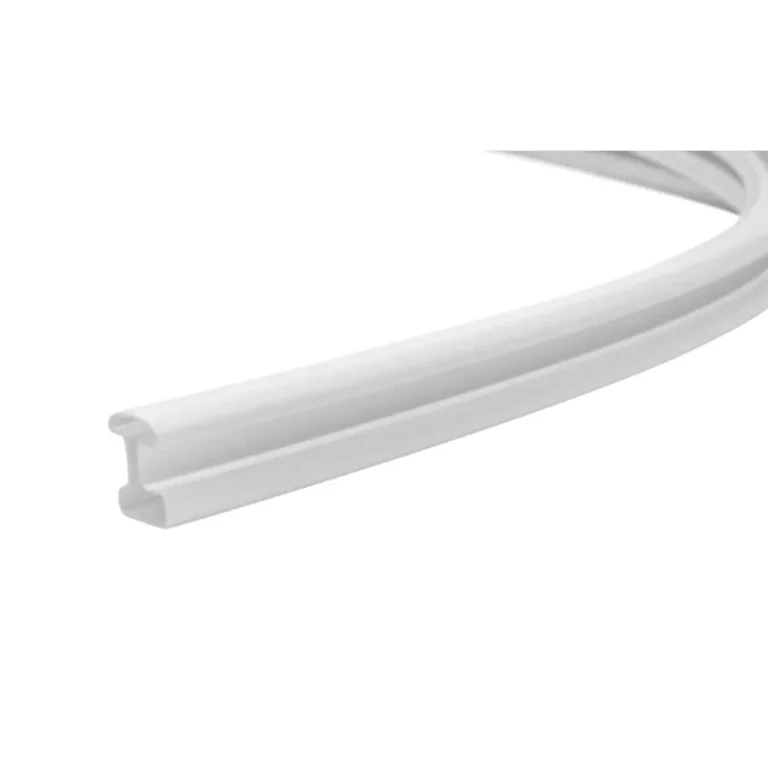

- Customizable: Available in various colors, sizes, thicknesses, and profiles (e.g., hollow, solid, multi-lumen) tailored to exact specifications.

Technical Specifications

Material: Acrylonitrile Butadiene Styrene (ABS) with high-flow modifiers

Density: 1.04–1.06 g/cm³

Tensile Strength: 40–50 MPa

Flexural Modulus: 2,000–2,400 MPa

Heat Deflection Temperature (0.45 MPa): 95–105°C

Melt Flow Rate (220°C/10 kg): 15–25 g/10 min

Standard Lengths: Up to 6 meters (custom lengths available)

Tolerance: ±0.1–0.3 mm (depending on profile complexity)

Compliance: RoHS, REACH, UL94 HB/V-2 (flame retardant options)

Applications

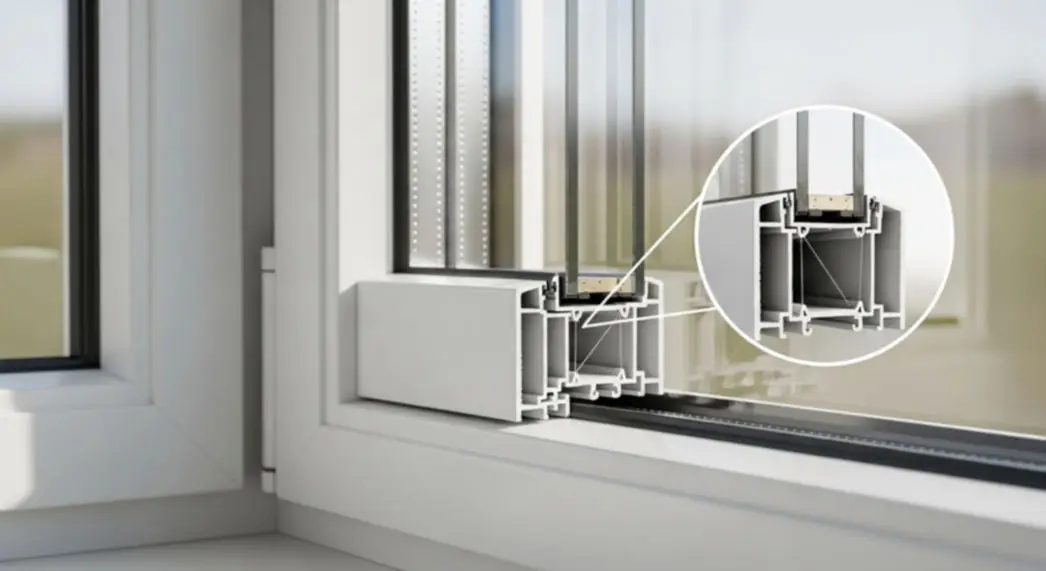

Widely used in automotive trims, HVAC housings, electrical enclosures, appliance components, point-of-sale displays, and architectural millwork. The high flowability and precision extrusion make these profiles ideal for intricate parts such as cable ducts, bezels, edge trims, and modular frames. Compared to PVC or UPVC, ABS offers better impact strength at lower temperatures, while outperforming PE in rigidity and surface hardness. For projects requiring both durability and aesthetic appeal, ABS profiles provide a balanced solution.

Why Choose This Product

Our profiles are manufactured using state-of-the-art extrusion lines with strict QC protocols, ensuring batch-to-batch consistency. With full customization capabilities—from profile design and material formulation to color matching and packaging—we deliver solutions tailored to your production needs. Explore our custom PVC profiles and our plastic extrusion solutions for additional material options and design support.

Partner with a manufacturer that prioritizes precision, efficiency, and innovation. Request a sample or consultation today to optimize your next project with high-performance ABS extrusions.

Dalang specializes in custom extrusion services for PVC, UPVC, ABS, PE, and other plastic materials, widely used in windows, doors, refrigerators, and various applications requiring precision plastic components.