Key Features

- High-Precision Tolerances: Engineered to ±0.15 mm dimensional accuracy, ensuring seamless integration in tight-tolerance assemblies.

- Material: Acrylonitrile Butadiene Styrene (ABS): Combines high impact resistance (Izod impact strength: 200–400 J/m), thermal stability (HDT: 80–100°C at 1.82 MPa), and excellent processability. Ideal for applications requiring durability and rigidity.

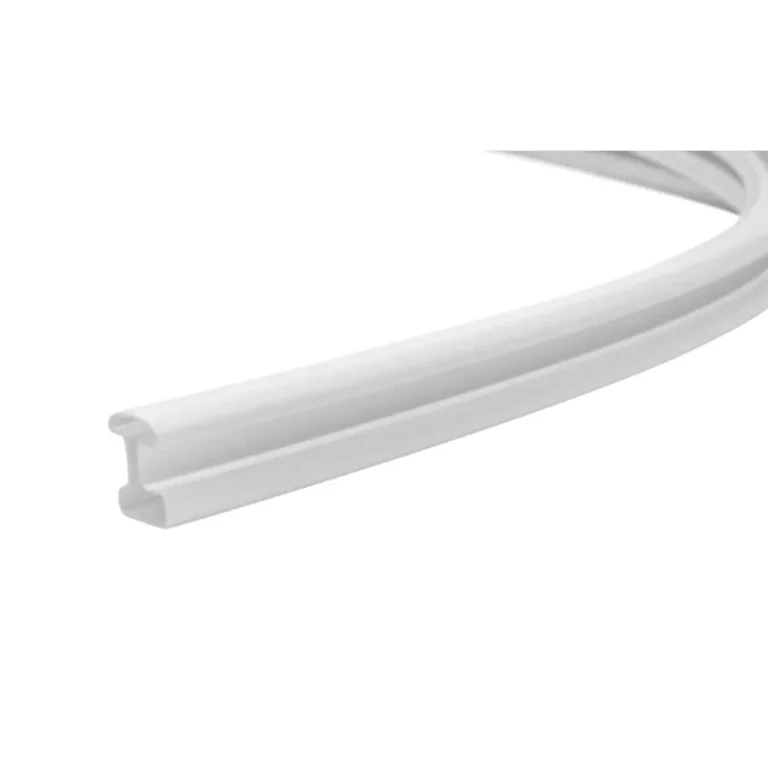

- Custom Geometry: Capable of producing complex cross-sectional profiles (e.g., hollow, multi-cavity, ribbed, or contoured designs) via advanced CAD/CAM modeling and multi-stage extrusion tooling.

- Surface Finish Options: Available in matte, gloss, textured, or custom patterns, with optional post-extrusion treatments (e.g., UV coating, flame retardant additives).

- Color Customization: Full RAL/Pantone color matching with consistent pigmentation throughout the profile.

- Quality Compliance: Manufactured to ISO 9001:2015 standards with 100% dimensional inspection and material traceability.

- Multi-Material Co-Extrusion: Optional integration of soft-touch TPE/TPU layers or rigid PVC/UPVC segments for hybrid functionality.

Technical Specifications

Profiles are extruded from virgin ABS resin (density: 1.04–1.07 g/cm³) with customizable wall thickness (0.5–15 mm) and lengths (up to 6 meters continuous). Key material properties include:

- Mechanical: Tensile strength: 40–50 MPa; Flexural modulus: 2.1–2.8 GPa

- Thermal: Operating range: -20°C to +80°C (short-term up to +100°C)

- Electrical: Volume resistivity: 1015 Ω·cm; Dielectric strength: 20 kV/mm

- Chemical Resistance: Resistant to alkalis, salts, and many acids (not suitable for strong solvents).

Tooling precision ensures ±0.1 mm repeatability across production batches. For projects requiring alternative materials, explore our plastic extrusion solutions, including rigid PVC (UPVC) for weatherability or HDPE for chemical resistance.

Applications

Designed for industries demanding precision and reliability:

- Automotive: Interior trim, dash components, door handles

- Electronics: Housings, bezels, structural frames for consumer/industrial devices

- Medical: Equipment enclosures, non-sterile instrument components

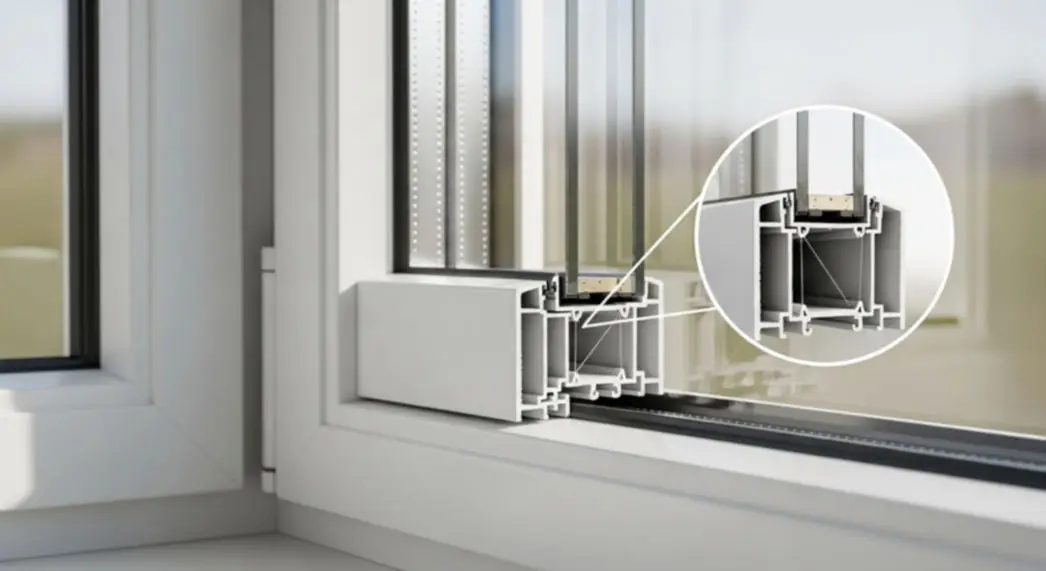

- Construction: Decorative moldings, window/door accessories, cable management

- Appliances: Refrigerator liners, vacuum cleaner housings, HVAC components

Why Choose This Product

This profile delivers unmatched design flexibility without sacrificing performance. Our closed-loop extrusion process minimizes material waste, reduces lead times, and supports rapid prototyping (2–4 weeks for custom tooling). Each profile undergoes rigorous QA, including laser gauging, tensile testing, and thermal cycling validation. Whether you need 500 or 50,000 units, our scalable production ensures cost efficiency and consistency.

Partner with Dalang to transform your design vision into high-performance extruded profiles. Request a quote today to leverage our engineering expertise and advanced manufacturing capabilities. Dalang specializes in custom extrusion services for PVC, UPVC, ABS, PE, and other plastic materials, widely used in windows, doors, refrigerators, and various applications requiring precision plastic components.