Custom Thin-Walled Design Extruded ABS Profiles (Thickness ≤ 1.8mm)

Engineered for precision and performance, Custom Thin-Walled Design Extruded ABS Profiles deliver exceptional strength-to-weight ratios, dimensional stability, and design flexibility for demanding industrial applications. With wall thicknesses as low as 1.8mm, these profiles are ideal for applications requiring lightweight components without sacrificing structural integrity. Made from Acrylonitrile Butadiene Styrene (ABS), these extrusions combine high impact resistance, chemical resilience, and excellent processability, making them a superior choice for automotive, appliance, electronics, and building sectors. Whether you need intricate cross-sections, tight tolerances, or custom color matching, our extrusion capabilities support fully tailored solutions to meet your exact specifications.

Key Features

- Ultra-Thin Wall Design: Wall thickness ≤ 1.8mm enables lightweight, material-efficient components ideal for space-constrained applications.

- High Impact Resistance: ABS material offers superior toughness even at low temperatures, outperforming standard PVC and PE in dynamic loading environments.

- Excellent Dimensional Stability: Low shrinkage and warpage ensure consistent part geometry and tight tolerances (±0.15mm typical).

- Chemical & UV Resistance: Resistant to oils, greases, and common solvents; UV-stabilized grades available for outdoor use.

- Customizable Profiles: Support for complex geometries, co-extrusion, dual durometer, and integrated functional features (e.g., snap-fits, channels).

- Color & Surface Options: Custom color matching (RAL, Pantone), matte, gloss, or textured finishes available.

- RoHS & REACH Compliant: Manufactured to meet international environmental and safety standards.

Technical Specifications

Material Properties (ABS)

- Density: 1.04–1.07 g/cm³

- Tensile Strength: 40–50 MPa

- Flexural Modulus: 2.1–2.5 GPa

- Heat Deflection Temperature (1.82 MPa): 85–95°C

- Flammability: UL94 HB standard; V-0 optional

Extrusion Capabilities

- Wall Thickness Range: 0.8–1.8mm

- Profile Width: Up to 300mm

- Tolerance: ±0.15mm (standard), tighter on request

- Length Options: Cut-to-length, continuous coils, or pre-assembled kits

Applications

These thin-walled ABS profiles are widely used in:

- Automotive: Interior trim, dashboard supports, cable management channels

- Appliances: Refrigerator liners, washing machine components, vacuum cleaner housings

- Electronics: Enclosure frames, connector housings, PCB supports

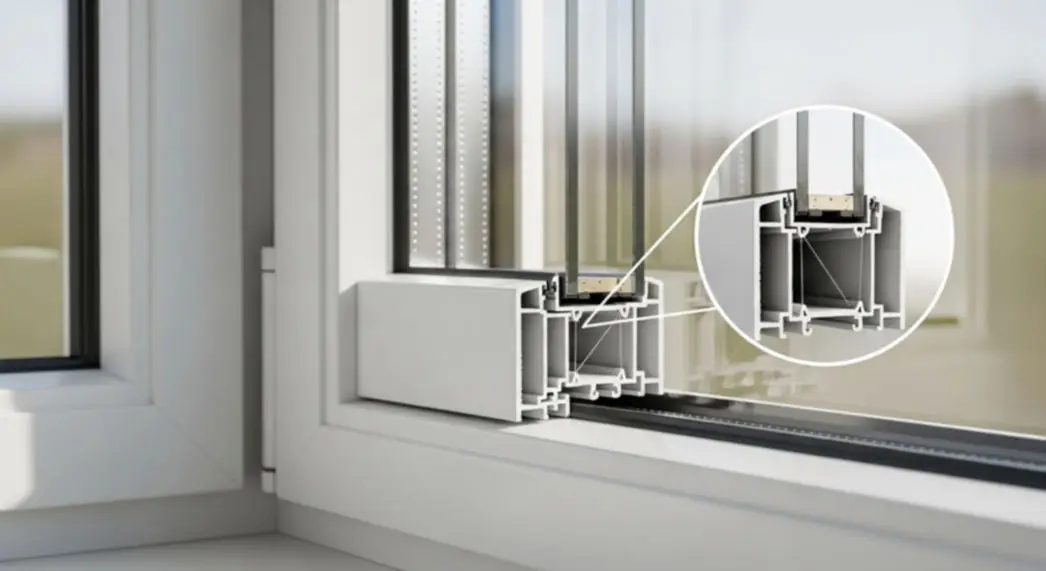

- Construction: Window/door gaskets, decorative moldings, HVAC ducting

- Furniture: Edging strips, modular shelving, display systems

Why Choose This Product

ABS outperforms traditional materials like PVC (less impact-resistant) and PE (lower rigidity) in applications requiring durability and precision. Unlike rigid UPVC, ABS offers greater toughness and lower notch sensitivity, reducing failure risk in dynamic environments. Our advanced extrusion lines enable rapid prototyping, high-volume production, and seamless integration with downstream processes. For our plastic extrusion solutions, we combine material science expertise with lean manufacturing to deliver cost-effective, high-quality profiles on time.

Dalang specializes in custom extrusion services for PVC, UPVC, ABS, PE, and other plastic materials, widely used in windows, doors, refrigerators, and various applications requiring precision plastic components. Contact us today to discuss your project requirements and request a sample.