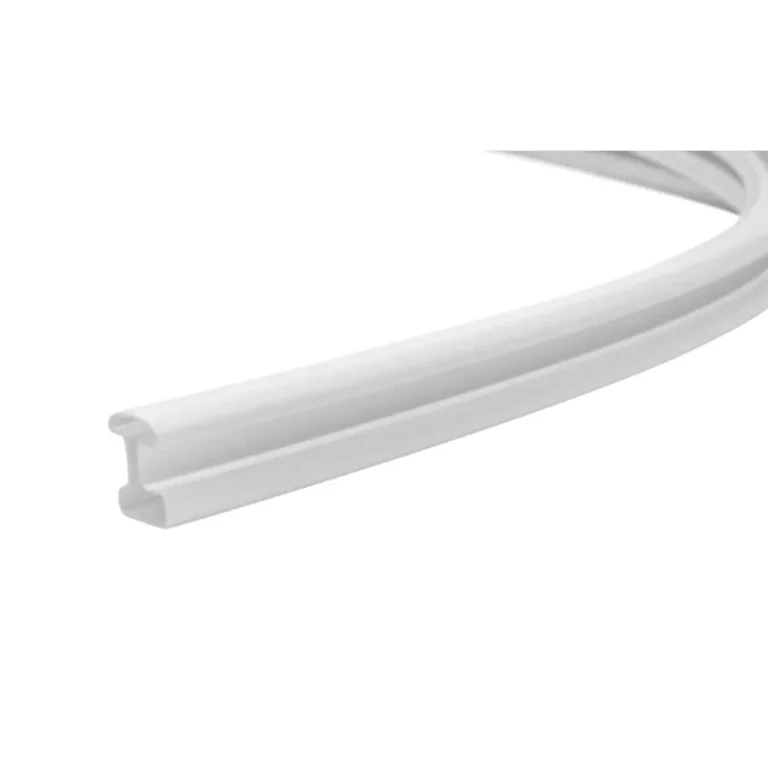

Customized Extruded PVC Base Profile: Precision, Durability, and Versatility

The Customized Extruded PVC Base Profile is a high-performance, engineered solution designed for industries requiring consistent dimensional accuracy, chemical resistance, and structural integrity. Manufactured using premium-grade polyvinyl chloride (PVC) or unplasticized PVC (UPVC), these profiles offer exceptional rigidity, weatherability, and flame resistance, making them ideal for demanding applications in construction, transportation, refrigeration, and industrial equipment. With advanced extrusion technology and strict quality control, these profiles can be tailored to meet specific mechanical, thermal, and aesthetic requirements, ensuring seamless integration into final assemblies.

Key Features

- Material Options: Available in rigid PVC, UPVC, ABS (for enhanced impact resistance), and HDPE (for superior moisture resistance), allowing selection based on application-specific needs.

- Custom Geometry: Precision extrusion enables complex cross-sections, multi-cavity designs, hollow chambers, and integrated fastening features to reduce secondary operations.

- Surface Finishes: Smooth, matte, textured, or co-extruded cap layers (e.g., ASA for UV stability) to match architectural or functional requirements.

- Flame Retardancy: Meets UL94 V-0 and V-2 standards, ideal for indoor and outdoor electrical enclosures and building components.

- Chemical & Moisture Resistance: Inherent resistance to alkalis, acids, and saltwater, suitable for marine and industrial environments.

- Thermal Stability: Low thermal conductivity and minimal expansion under temperature fluctuations (-20°C to +60°C operational range).

- Recyclable & Eco-Friendly: Fully recyclable materials compliant with RoHS, REACH, and other environmental regulations.

Technical Specifications

Material Properties

- Density: 1.38–1.45 g/cm³ (PVC/UPVC)

- Tensile Strength: 45–60 MPa (PVC), 40–55 MPa (ABS)

- Flexural Modulus: 2,500–3,000 MPa

- Heat Deflection Temperature: 65–75°C (at 1.82 MPa)

- Shore Hardness: 80–90 D (PVC), 100–110 R (ABS)

Customization Parameters

- Cross-sectional dimensions up to 300mm width, 150mm height

- Wall thickness: 0.8–8.0mm (varies by material and design)

- Length: Standard 2m, 4m, or custom-cut with ±0.5mm tolerance

- Color matching via RAL/Pantone standards or custom formulations

Applications

These profiles serve as foundational components in:

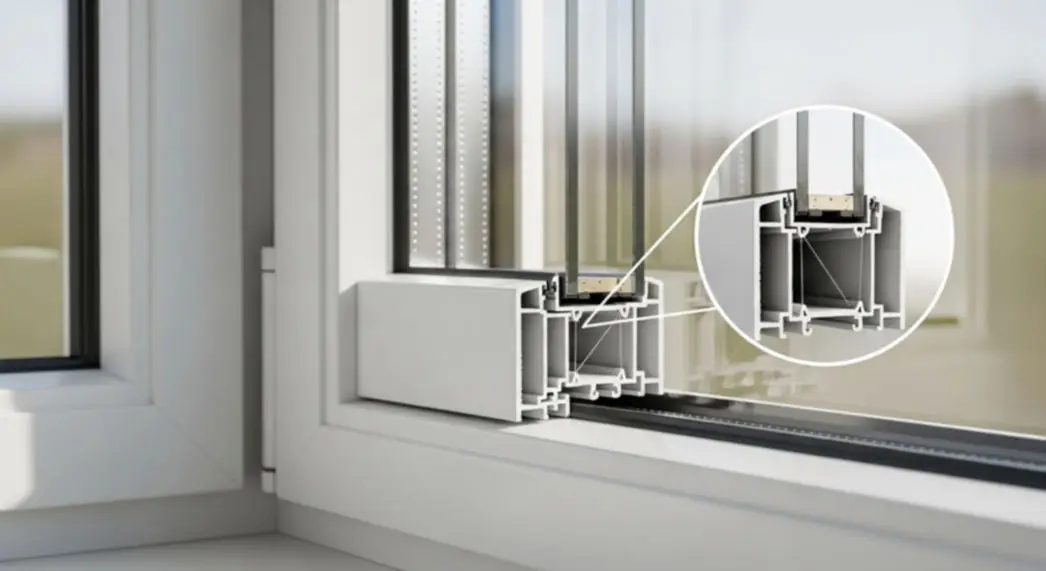

- Window and door framing systems (base tracks, sill extensions)

- Refrigerator cabinet insulation and sealing channels

- Industrial equipment base rails and mounting brackets

- Architectural trims, skirting boards, and flooring transitions

- Electrical conduit supports and cable management housings

Why Choose This Product

Dalang’s custom PVC profiles combine engineering excellence with scalable manufacturing. Our in-house tooling design, rapid prototyping, and ISO 9001-certified production ensure consistent quality, short lead times, and cost-effective solutions. Whether you need a simple linear profile or a complex multi-functional extrusion, our team delivers precision components that reduce assembly time, improve product lifespan, and enhance end-user performance. Explore our full range of our plastic extrusion solutions to find the ideal fit for your project.

Dalang specializes in custom extrusion services for PVC, UPVC, ABS, PE, and other plastic materials, widely used in windows, doors, refrigerators, and various applications requiring precision plastic components.