Customized Extruded PVC Drainage Channel: Precision Engineered for Efficient Water Management

The Customized Extruded PVC Drainage Channel is a high-performance solution designed to meet the demanding requirements of modern drainage systems in industrial, commercial, and residential applications. Manufactured from premium-grade polyvinyl chloride (PVC) or unplasticized PVC (UPVC), these channels offer exceptional chemical resistance, mechanical strength, and dimensional stability. Ideal for environments requiring corrosion-resistant, lightweight, and durable water conveyance systems, our drainage channels are engineered for seamless integration into flooring, rooftops, parking structures, and industrial facilities. With full customization capabilities—including dimensions, cross-sectional profiles, load ratings, and surface finishes—our extrusion process ensures optimal flow dynamics and long-term reliability.

Key Features

- Material Options: Standard PVC for general-purpose applications; UPVC for enhanced rigidity and UV resistance; optional ABS or HDPE for high-impact or low-temperature environments.

- Corrosion & Chemical Resistance: Inert to acids, alkalis, salts, and most industrial chemicals, ideal for wastewater and aggressive media handling.

- High Load-Bearing Capacity: Structurally reinforced profiles available in Class A (up to 10 kN) to Class D (up to 90 kN) per EN 1433 standards.

- Custom Cross-Sections: U-shaped, V-shaped, or trapezoidal profiles with integrated grating grooves, end caps, and connection flanges.

- Smooth Internal Surface: Low-friction coefficient (Ra < 0.8 µm) minimizes sediment buildup and maximizes hydraulic efficiency.

- Thermal Stability: Operating range from -20°C to +60°C (PVC), up to +80°C (UPVC).

- Eco-Friendly & Recyclable: 100% recyclable materials compliant with RoHS and REACH regulations.

Technical Specifications

Material Properties

- Density: 1.3–1.45 g/cm³ (PVC/UPVC)

- Tensile Strength: 50–60 MPa (PVC), 55–65 MPa (UPVC)

- Flexural Modulus: 2,800–3,500 MPa

- Water Absorption: <0.2% (24h immersion)

- Flame Retardancy: Self-extinguishing (UL94 V-0 optional)

Standard Dimensions

- Width: 50 mm – 600 mm (customizable)

- Depth: 40 mm – 500 mm

- Length: 1 m – 6 m (standard), up to 12 m (custom)

- Wall Thickness: 2.5 mm – 8 mm (application-dependent)

Applications

These drainage channels are engineered for use in:

- Industrial flooring (chemical plants, food processing)

- Commercial kitchens and laboratories

- Parking decks and rooftop terraces

- Swimming pool surrounds and locker rooms

- Agricultural drainage and greenhouse systems

- Public infrastructure (railway platforms, airports)

Why Choose This Product

Our custom PVC profiles are produced using advanced co-extrusion and profile extrusion lines, ensuring tight tolerances (±0.2 mm), consistent wall thickness, and repeatable quality. Each channel is manufactured under ISO 9001:2015 quality management systems, with optional third-party certification for load performance and material compliance. With in-house tooling design and rapid prototyping, we deliver tailored solutions in as little as 15 days—perfect for project-specific requirements or OEM integration. Explore our plastic extrusion solutions to optimize drainage performance and lifecycle cost.

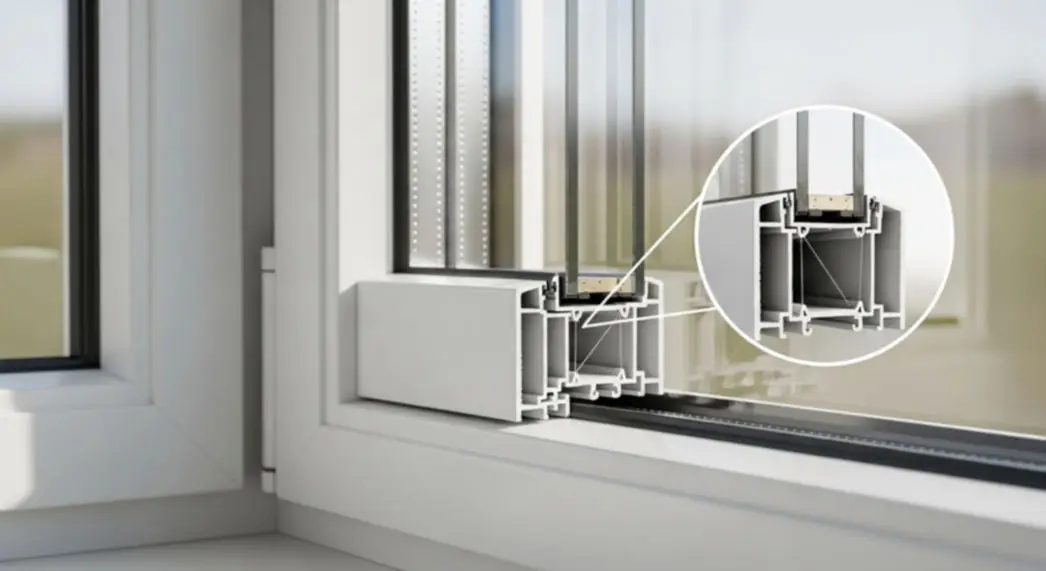

Dalang specializes in custom extrusion services for PVC, UPVC, ABS, PE, and other plastic materials, widely used in windows, doors, refrigerators, and various applications requiring precision plastic components.