Customized Extruded PVC Frame Profile: Precision, Durability, and Versatility

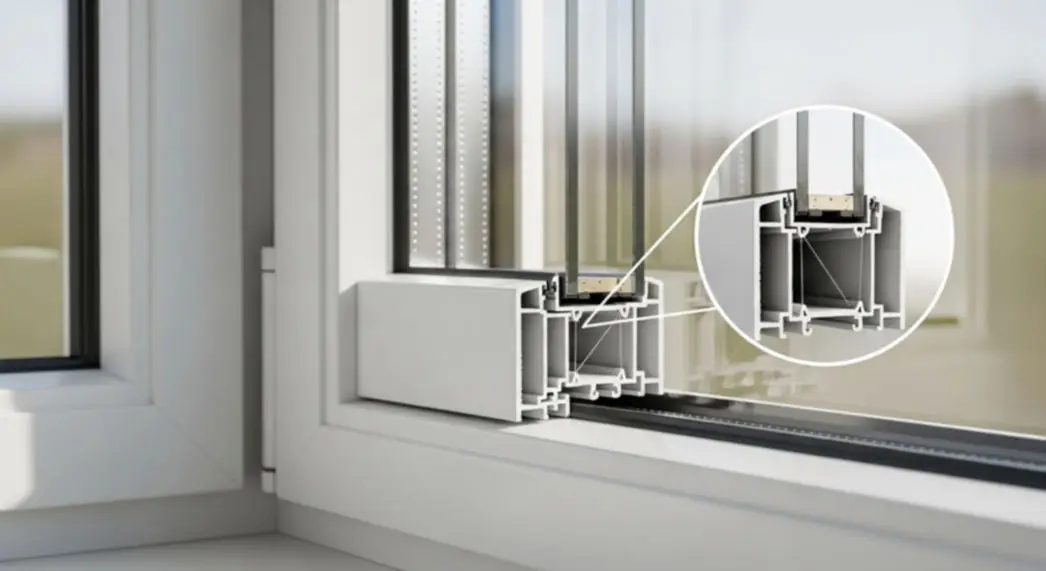

The Customized Extruded PVC Frame Profile is engineered to meet the demanding requirements of modern industrial and architectural applications. Fabricated from high-grade polyvinyl chloride (PVC) or unplasticized PVC (UPVC), these profiles offer exceptional dimensional stability, weather resistance, and mechanical strength. Ideal for window and door systems, refrigeration components, and modular enclosures, this product delivers long-term performance in both indoor and outdoor environments. With advanced extrusion technology and full customization capabilities, our profiles are tailored to your exact specifications—ensuring seamless integration into your manufacturing process. Explore our plastic extrusion solutions for end-to-end support from design to delivery.

Key Features

- Material Options: Available in rigid PVC (UPVC) for structural applications, flexible PVC for sealing and gaskets, and co-extruded combinations with ABS or PE for enhanced impact resistance and surface finish.

- UV & Weather Resistance: Formulated with UV stabilizers and anti-oxidants for extended outdoor durability, preventing yellowing, cracking, and degradation.

- Thermal & Electrical Insulation: Low thermal conductivity (0.14–0.28 W/m·K) and excellent dielectric properties (volume resistivity >10¹⁴ Ω·cm) ideal for energy-efficient and electrical-safe applications.

- Chemical Resistance: Resistant to acids, alkalis, salts, and most industrial solvents—suitable for harsh environments.

- Custom Geometry & Tolerances: Profiles manufactured to ±0.1 mm dimensional accuracy with complex cross-sections, hollow chambers, and multi-wall structures.

- Surface Finishes: Options include matte, glossy, wood-grain, or textured finishes; compatible with printing, laminating, and co-extrusion for branding or functional layers.

Technical Specifications

Material Properties (UPVC Standard Grade)

- Density: 1.3–1.45 g/cm³

- Tensile Strength: 45–60 MPa

- Flexural Modulus: 2,800–3,500 MPa

- Vicat Softening Point: 75–85°C

- Linear Thermal Expansion: 6–8 × 10⁻⁵ /°C

- Flame Retardancy: UL94 V-0 (on request)

Profiles available in standard lengths up to 6 meters, with custom lengths, color matching (RAL/Pantone), and dual-color extrusion capabilities.

Applications

Widely used in:

- Window and door frames (thermal break systems)

- Refrigerator and freezer cabinet liners

- Modular partition walls and cleanroom panels

- Electrical cable management and conduit systems

- Furniture edge trims and display fixtures

- Agricultural greenhouse structures and irrigation components

Why Choose This Product

Dalang’s extrusion process adheres to ISO 9001:2015 quality standards, with rigorous in-line laser measurement, automated quality control, and batch traceability. Our engineering team collaborates with clients to optimize profile design for material efficiency, structural performance, and ease of assembly. From prototype to high-volume production, we deliver consistent, high-precision custom PVC profiles with fast turnaround and global logistics support.

Contact us today to discuss your project requirements and receive a technical consultation. Dalang specializes in custom extrusion services for PVC, UPVC, ABS, PE, and other plastic materials, widely used in windows, doors, refrigerators, and various applications requiring precision plastic components.